“There’s a sense of care and thought in terms of balancing the shade’s cost and production with its aesthetics, architectural value, and environmental value.” —Juror Tom Chung, AIA

In designing a six-story, 497,000-square-foot science and engineering complex for Harvard University, Behnisch Architekten faced two daunting tasks: how to minimize the energy load of the massive building, conceived as a series of large glass boxes; and how to minimize the enormous structure’s scale in Allston, a low-slung, academic and residential neighborhood across the Charles River from the university’s main campus in Cambridge, Mass. “We had a scaleless façade cladding, and we wanted to mask all that with a textured façade,” says Boston-based Behnisch partner Robert Noblett, AIA.

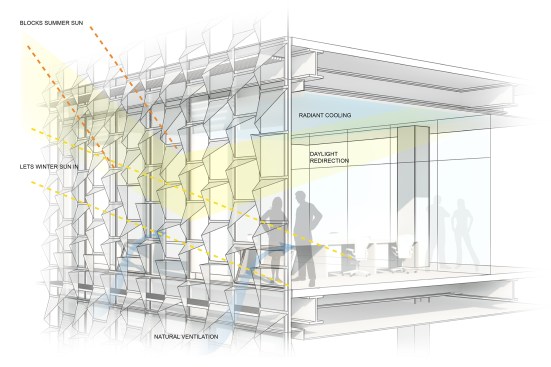

The solution was the development of a shading system that could pull double duty as a cooling mechanism and as a visual break in the building mass—and be lightweight enough to be installed on the façade with minimal structural support.

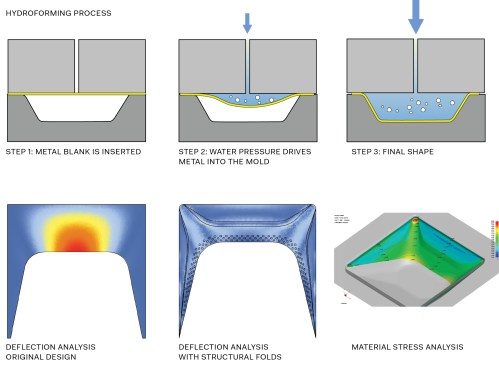

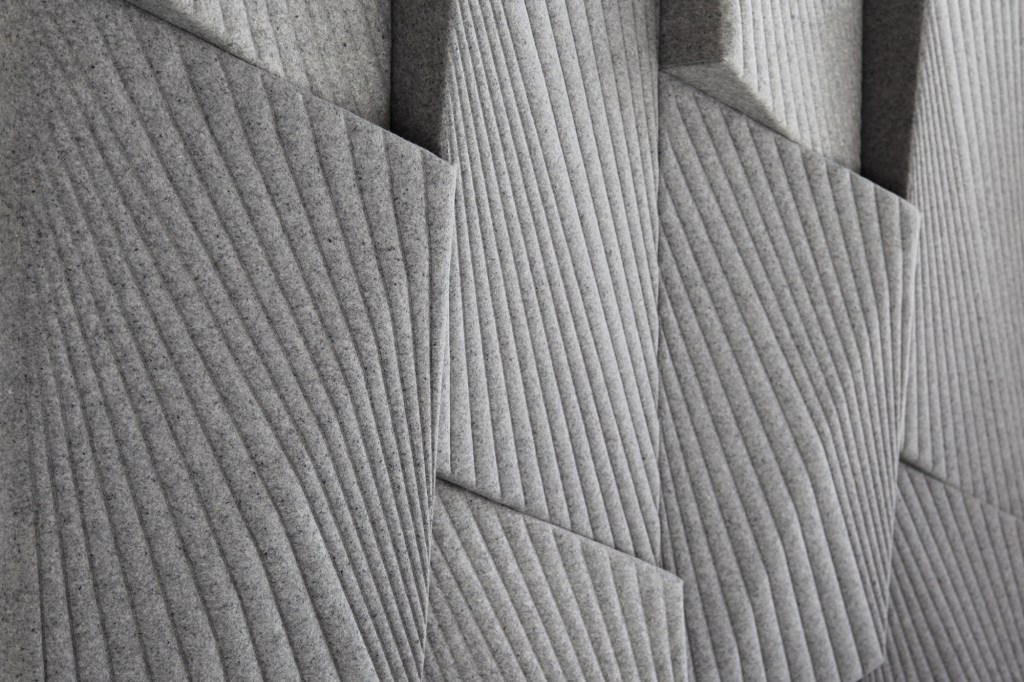

Inspired by the shapes, strength, and thinness of everyday objects like tin cans and soup bowls, Behnisch worked with German fabricator Edelstahl-Mechanik to create the world’s first hydroformed tensile façade. Common in the aerospace industry, hydroforming uses water pressure to shape ultrathin metal plates against a mold, creating custom pieces.

Janis Rozkalns

Full-scale visual mock-up

Courtesy Behnisch Architekten

Hydroforming process and material strength analysis

Janis Rozkalns

North elevation panel in mold

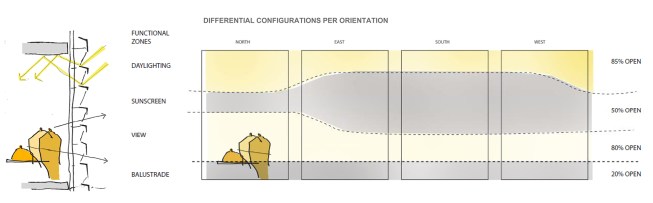

At one point, Behnisch considered using the same metal piece across the façade, but making it adjustable. However, Noblett says, that would require a motorized system, which would drain energy and introduce potential maintenance issues.

Instead, Behnisch stipulated 14 different shapes, varying in size and the number of facets, to maximize heat and light reflection at different points across the building façade. Just 1.5mm thick and weighing 10 pounds each, the 12,000 hydroformed plates are also perforated around the edges to allow in diffused light while minimizing heat intake. Despite their thin profile, the panels are strong enough to be connected directly to spring-tensioned steel cables attached to the building at the spandrels, which have auxiliary wind bracing.

The result, Noblett says, is a shading solution “as flexible and responsive as a motorized system, but fixed in place.” The system reduces the building’s peak cooling load by 65 percent, reflects natural light deep into the interior, and visually breaks up the building mass.

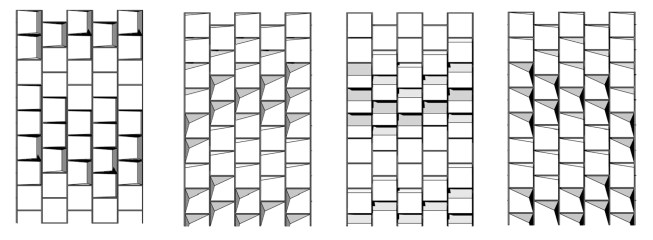

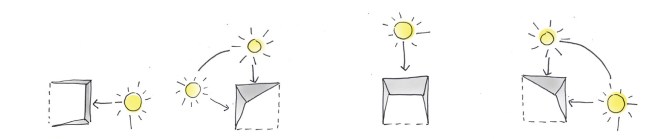

Courtesy Behnisch Architekten

Façade performance diagram

Courtesy Behnisch Architekten

Courtesy Behnisch Architekten

Elevations (Left to Right): north, east, south, and west

Courtesy Behnisch Architekten

Module shape per window orientation (Left to Right): north, east, south, west

Janis Rozkalns

Hand-finishing and quality control inspection of a panel

Janis Rozkalns

Full-scale mock-up

Project Credits

Project: Hydroformed Shading

Client: Harvard University

Design Firm: Behnisch Architekten, Boston

Collaborators: Knippers Helbig, Josef Gartner, Edelstahl-Mechanik

Façade Consultant: Knippers Helbig

Façade Contractor: Josef Gartner

Fabricator: Edelstahl-Mechanik

Structural Engineer: BuroHappold Engineering

M/E/P Engineer: van Zelm Heywood & Shadford

Civil Engineer: Nitsch Engineering

Geotechnical Engineer: BuroHappold Engineering

Climate Engineering: Transsolar

Construction Manager: Turner Construction Co.

General Contractor: Turner Construction Co.

Landscape Architect: Stephen Stimson Associates Landscape Architects

Lighting Designers: Bartenbach, Lam Partners

Interior Designer: Behnisch Architekten

Note: The project credits have been updated since first publication to correct the location of the Behnisch Architekten office that led this project.

-

Citation: Buoyant Ecologies Float Lab Aims to Save Communities Above and Below Water

To preserve and promote indigenous marine life, the Architectural Ecologies Lab at the California College of the Arts turned to the phenomenon of biofouling.

-

Citation: Limb, a Fantastical Take on Timber Construction

University of Michigan faculty members Steven Mankouche, Peter von Bülow, and Kasey Vliet leverage the inherent strength of tree crotches to create 3D structures.

-

Citation: MineralBuilt, a New CMU Block Designed by Architects

In searching for a product with the strength of concrete but flexibility of wood framing, Francisco Gomes and Dabney Staub created their own building block.

-

Citation: Robotic Needle Felting Stitches New Possibilities

University of Michigan faculty members Tsz Yan Ng, Wesley McGee, and Asa Peller take the age-old process to the next level: automation.

-

Citation: Thinness Redefines Lightweight Concrete

Aptum Architecture, in Syracuse, N.Y., and global concrete manufacturer Cemex create a 10-foot-tall pavilion with walls that are a mere 2 centimeters thick.

-

Honorable Mention: Functional Façade, Made with a Robot for Cornell Tech’s Emma and Georgina Bloomberg Center

Automation helped Morphosis and A. Zahner Co. realize a bespoke rainscreen for the innovative academic building in New York.

-

Honorable Mention: Here East Gantry, a Medley of Studios From a Kit of Parts

HawkinsBrown Architects deploys WikiHouse software to output 23 memorable studios in a steel gantry in London.

-

Honorable Mention: Hydroformed Shading, a Metal Feature Shaped by Water

For Harvard University's Paulson School of Engineering and Applied Sciences, Behnisch Architekten created a system that would minimize the building's energy load and maximize visual interest.

-

Honorable Mention: Precautionary List, a User-Friendly Guide to Green

As part of Perkins+Will's effort to make the construction process more transparent, the firm created a free, online database of materials and chemicals often found in building products.

-

Honorable Mention: Social Sensory Architectures Offers Comfort and Healing Through Design

University of Michigan assistant professor Sean Ahlquist explores the impact of architecture on autism and sensory processing disorder.