Blair Satterfield

Built prototype detail

The “aha!” moment at the University of British Columbia’s HiLo Lab came when researchers, intent on bending strips of wood veneer into unusual forms, stepped back to look at their elaborate setup. “We realized we could use the formwork itself as the member,” says Blair Satterfield, chair of UBC’s architecture program and an associate professor.

That breakthrough led to zippered wood, which leverages ordinary construction methods to create extraordinary structures with the humble 2×4. “We thought about the project both formally, in terms of what we can achieve cheaply and quickly with standard studs, and also in a performative way, in terms of efficiency and strength,” says Marc Swackhamer, Assoc. AIA, who chairs the architecture department at University of Colorado, Denver and co-founded HouMinn Practice with Satterfield.

courtesy University of British Columbia, HiLo Lab, University of Colorado, Denver, LoDo Lab, HouMinn Practice

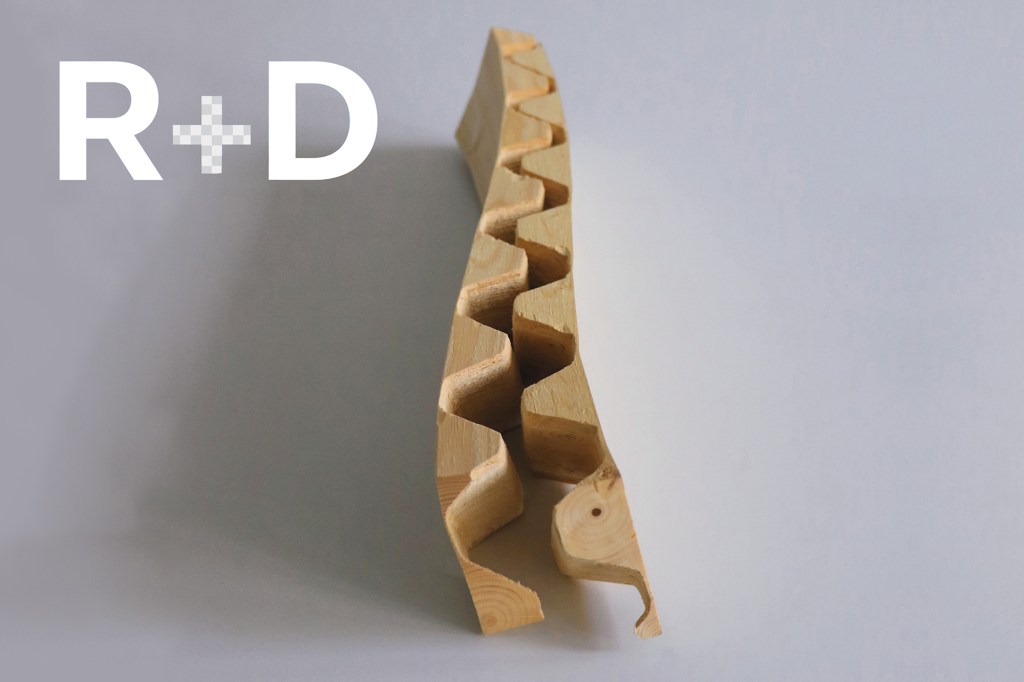

Once milled, the two unique halves are paired together. The "valleys" are flexible enough to bend and twist, while the tooth pattern registers the boards.

Derek Mavis

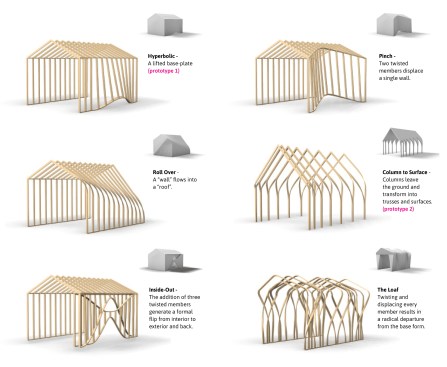

Framing possibilities through zippered wood

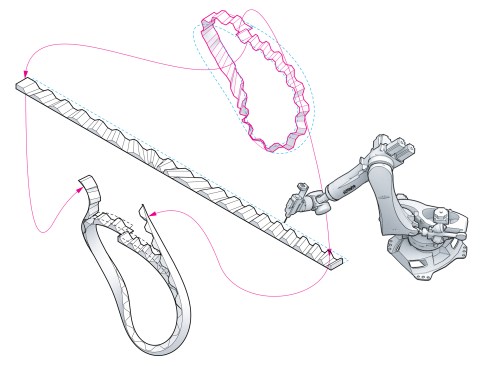

Starting with a cross-cut saw, the team created kerfs along 2×4s, enabling them to bend and twist. Using Grasshopper and the Kangaroo plug-in, they modeled the results and then wrote software protocols to map tooth patterns to specific curvatures. They upgraded to a CNC mill to cut teeth into 2×4s in such a way that two separate pieces of wood would lock or “zipper” only when they are hand-twisted together into the desired position, no wood steaming or soaking required. The mated pieces are clamped and glued to form a curving composite member with the dimensional cross-section of a 2×4. “Anecdotally, these bent and joined members are much stronger than a straight stud,” Satterfield says. “It’s unbelievable how much force they can take.”

To demonstrate their project’s potential and software’s accuracy, the team built and exhibited two full-scale prototypes on the UBC campus in 2019: a common stud wall with a base plate replaced with a curving zippered beam, creating a hyperbolic paraboloid bulge; and a cultural pavilion that uses zippered members, some twisting 135 degrees, to obviate the wall-roof connection.

Through this analysis of standard sizes and fabrication methods, the team came up with something very sinuous, beautiful, and surprising from a 2×4.

—Juror Ming Thompson, AIA

The team is further streamlining the fabrication technique by scanning each board and using a script to adjust the design to avoid knots and holes. Most exciting, Swackhamer says, is the “democratizing potential” of a technique that broadens the possibilities of stick-frame construction.

Alex Preiss

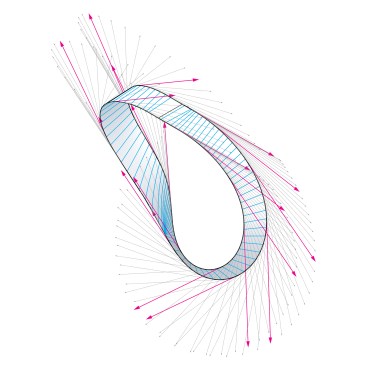

For any given point on one 3D edge of the virtual 2×4, the team's script compares its tangency to thousands of sample points on the opposite target edge.

Alex Preiss

Rule lines generated through analysis create a tooth pattern that manifests the desired curve. A CNC mill or robot follows the virtual, unrolled tool pattern into a 2×4. The pattern is mated to a second milled board, forming the designed curvature in the resulting 2×4.

courtesy University of British Columbia, HiLo Lab, University of Colorado, Denver, LoDo Lab, HouMinn Practice

Generating consistent outcomes took the team time. This cylinder test mated multiple zipped 2x4s together around an implied cylinder. The test's success gave the team confidence to try erecting a small structure.

courtesy University of British Columbia, HiLo Lab, University of Colorado, Denver, LoDo Lab, HouMinn Practice

The long-span zippered 2×4 comprises multiple pieces of scrap wood. The unique tooth pattern required to make the bend is expressed on the side edge of the composite member. The resulting stud wall has a parabolic form.

courtesy University of British Columbia, HiLo Lab, University of Colorado, Denver, LoDo Lab, HouMinn Practice

This zippered wood prototype explores the formal capacity of the research by producing a modified bay of an outdoor pavilion designed to house student performances or impromptu teaching spaces. Left: Rendering of a complete structure using repurposed timber converted into zippered wood members. Right: The built, one-bay structure both reminds visitors of conventional construction while subverting the logic of a stud wall.

Blair Satterfield

Some zippered wood members used in the prototype twisted 135 degrees.

Project Credits

Project: Zippered Wood

Location: School of Architecture and Landscape Architecture, University of British Columbia, Vancouver, British Columbia

Client/Owner: UBC HiLo Lab

Support: Ecowaste Industries; Foundation For The Carolinas; UBC SEEDS Sustainability Program

Architect/Designer Team: UBC HiLo Lab . Blair Satterfield (director), Alexander Preiss, Derek Mavis, Graham Entwistle; University of Colorado, Denver LoDo Lab . Marc Swackhamer, Assoc. AIA (director), Matthew Hayes; HouMinn Practice . Blair Satterfield (principal), Marc Swackhamer (principal)

Size, Final Prototype: 48 square feet

Cost: $45,000CAD (approximately $33,000 USD)

This article has been updated since first publication.

-

14th Annual R+D Awards

From 90 submissions, the jury picked seven entries that are scalable, thought-provoking, and promising in achieving a more equitable and healthy built environment.

-

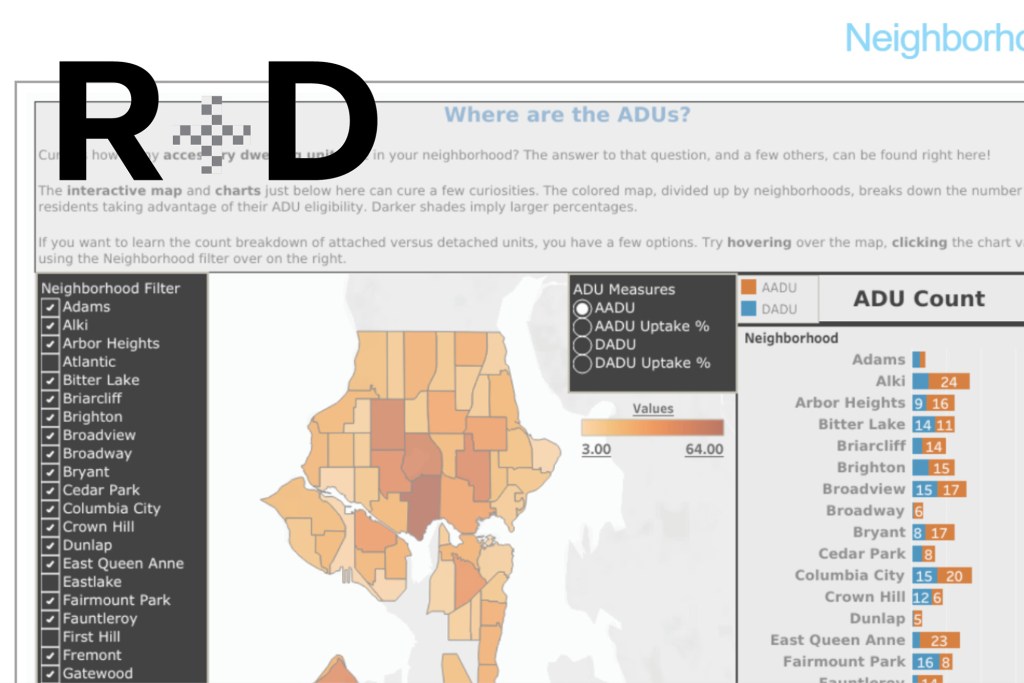

Award: ADUniverse, an App to Increase Housing Access

University of Washington associate professor Rick Mohler and the city of Seattle senior planner Nick Welch created a prototype app to help local homeowners increase housing density by building accessory dwelling units.

-

Award: Empathic Design Process Aims to Identify Successful Environments Through Data

A bike trip across the Netherlands inspired lead engineer Mike Sewell and Gresham Smith's Studio X Innovation Incubator to improve design by quantifying emotional response.

-

Award: InVert Self-Shading Windows Flip Energy Efficiency On Its Head

TBM Designs, co-founded by thermobimetal innovator Doris Sung, is tucking a self-powered, kinetic solution within insulated glass units to reduce solar heat gain and glare into buildings.

-

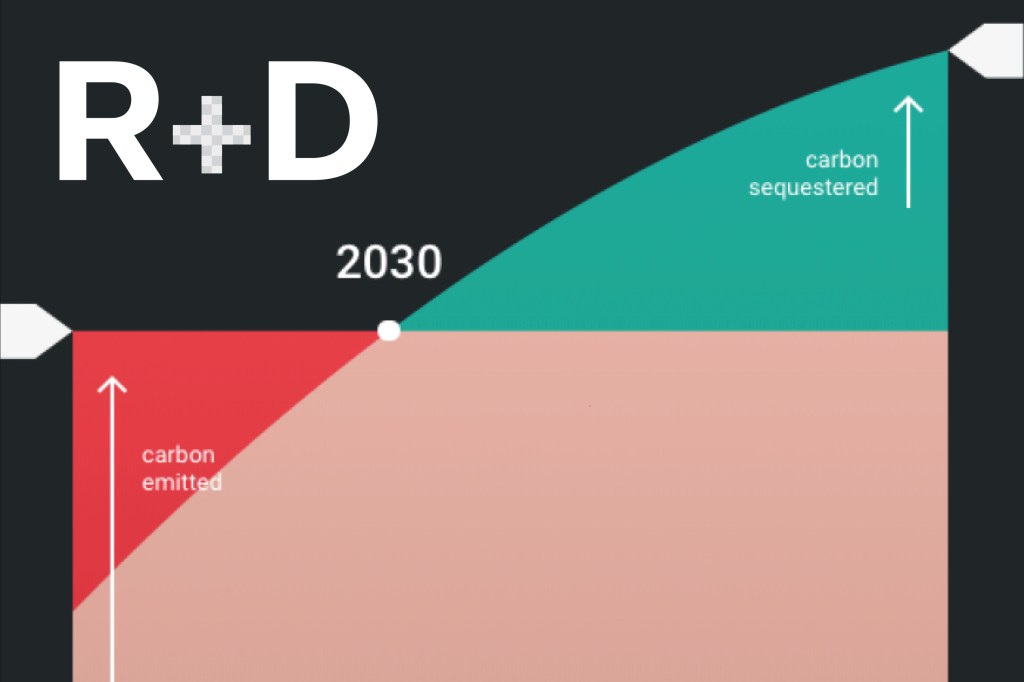

Award: Pathfinder, an App to Reduce Embodied Carbon in Landscape Design

Designed and developed by CMG Landscape Architecture, the mobile app enables designers to approximate the impact of their projects' materials and maintenance on carbon emissions.

-

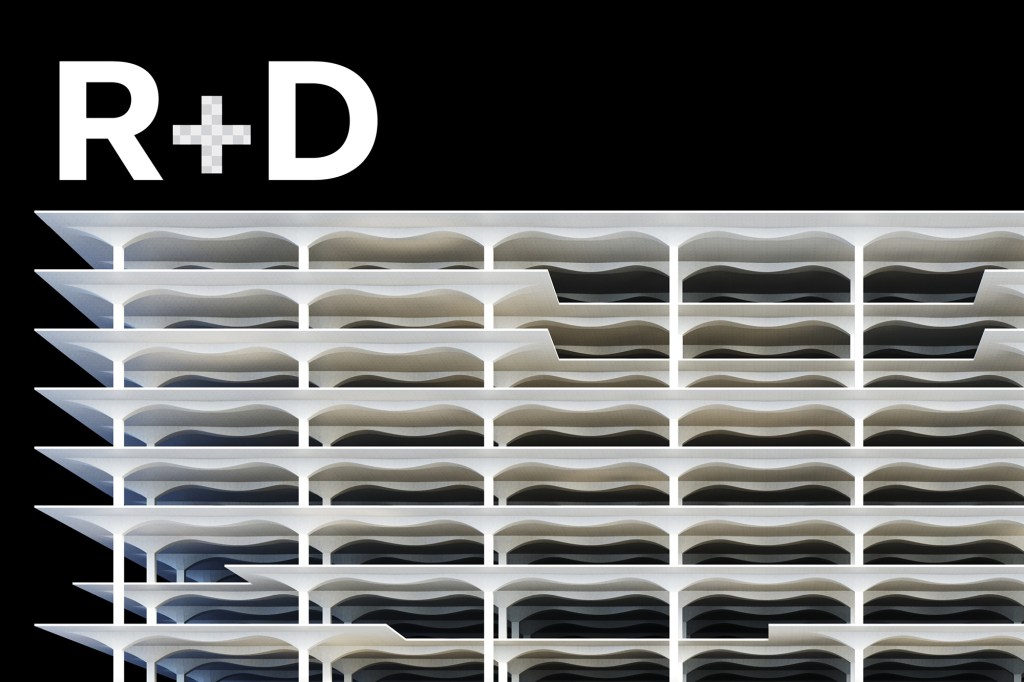

Award: Stereoform Slab’s Optimized Structure Reduces Embodied Concrete

Skidmore, Owings & Merrill developed an undulating "smart band beam" to support a concrete slab at half the thickness of a typical flat plate.

-

Award: Walking Assembly Is Poetry and Structure in Motion

Matter Design and cement producer CEMEX converted their shared fascination with "embedding intelligence into objects" into megalith units that are surprisingly maneuverable.

-

Award: Zippered Wood Twists the Standard 2×4 to Craft New Forms

Researchers at the University of British Columbia's HiLo Lab, University of Colorado, Denver's LoDo Lab, and HouMinn Practice push the potential of the ubiquitous wood member.