From Nov. 13–15, approximately 11,000 architects, designers, builders, and CAD users attended Autodesk University, one of the largest technology conventions in the AEC industry. The annual event, held at the Venetian Hotel in Las Vegas, attracts attendees worldwide interested in industry trends and software developments.

The pace of convention was frantic—attendees literally raced up and down escalators to reach the different rooms hosting dozens of workshops and lectures simultaneously. The numerous topics covered catered to the wide range of attendee interests; I, for one, attended everything I could on robotics and virtual reality (VR). As in recent years, a main theme of this year’s event was the future of work.

When “Better” Equals Automation

One of the most anticipated events at AU is always the main stage keynote, during which Autodesk presents its newest products and aspirations. CEO Andrew Anagnost, with guest appearances that included Erin Brader from Autodesk’s Robotics Lab, and author and former GE vice chair Beth Comstock, projected his vision across seven screens complete with surround sound: The AEC community will benefit from automation. In the future, he charged optimistically, we will be able to make more things—and better, with less negative impact on the environment. He emphasized “the opportunity of better.”

Terri Peters

The Valk Welding group showcased two Panasonic TS-950 robots for directed energy deposition (DED), a form of additive manufacturing that produces large, strong, and usable metal components. Autodesk envisions this shipping container as part of a large-scale, self-contained, additive-manufacturing toolbox that delivers robots to construction sites with their own work environment.

Courtesy Autodesk

In the main stage keynote, Beth Comstock, author of Imagine It Forward: Courage, Creativity, and the Power of Change (Currency, 2018), advised attendees to become comfortable living “at the intersection of changing technologies whose impacts are not fully clear or scaled.” She described several companies that spotted opportunities to adapt and enter new markets and movements ahead of the trend.

But what does “better” really mean here? Anagnost offered some provocations. With automation handling tasks humans would rather not, people could focus on more creative work. If accurate data could be shared more reliably, teams would be able to rely on cloud-based tools as “a single source of truth,” and thus collaborate better. He described time-saving refinements to existing Autodesk products, like BIM 360’s new document log feature that automates reporting and documentation, a tedious task for the project team.

While these upgrades will likely move the AEC community toward the future of work, it will be in incremental steps. So what new developments and tools are set to truly change things up?

Beyond AEC

In the most striking example of what the future of work could mean for architects, Anagnost revealed an interplanetary lander prototype designed in a collaboration between Autodesk and NASA’s Jet Propulsion Laboratory. The lander’s lightweight and efficient form captivated the crowd as Anagnost detailed how Fusion 360, Autodesk’s generative design software, was used to improve the device’s projected performance and fabricate it digitally.

Terri Peters

A collaboration between NASA and Autodesk, the fully-assembled lander—the most complicated structure ever created using generative design—measures approximately 8 feet long and 3 feet tall. Autodesk assembled the components of the interplanetary lander at its technology center in San Francisco. As the project was unveiled during the mainstage keynote, Autodesk robotics director Erin Bradner said, “Its goal is to explore and its task is to land.”

Another key message expressed at AU was that the future of work for the AEC community will require considering tools and perspectives from other disciplines. To date, generative design’s impact on architecture has been limited; one example is the interior of Autodesk’s Toronto offices, in which the The Living set parameters of adjacency, quality of space, light, among others, and let the software find optimal interior layouts satisfying the criteria.

How soon will the AEC community embrace this design and manufacturing method in building fabrication? Anagnost didn’t share any examples of generative design components for buildings—no façades, skylights, or staircases—but the AU Expo did showcase a range of industrial components fabricated using Fusion 360, including prototypes from General Motors’ collaboration for 3D printed seat brackets and innovations in car and motorcycle design.

Courtesy Autodesk

During the main-stage keynote, New York–based computational designer Nidhi Sekhar of LERA Consulting Structural Engineers described how she used “algorithm-aided design” through Dynamo and other Autodesk software to optimize her workflow while preserving her design vision as part of the firm’s research and design group LERA+.

Visualizing, Not Estimating

It seems safe to say that 2019 will be the year that more architects experiment with virtual reality (VR). On day two of AU, inspiration came from the gaming industry. Unity CEO John Riccitiello announced that native export for Unity in Revit will be available for data visualization in fall 2019. Unity is the most widely used, real-time, 3D development platform, best known for powering more than 50 percent of the gaming industry. While some designers currently use Unity and the Oculus Rift headset for visualization, this newfound interoperability between Revit and Unity could be the push that entices designers unfamiliar with gaming.

Unity vice president and general manager Tim McDonough explained that this new functionality of exporting directly from Revit to Unity, without the loss of BIM data, will offer a new experience of virtually walking through a building. There is no button to push to send the image to render—Unity automatically visualizes and updates models providing up to date feedback. McDonough explains, “You can play a computer game—now you can play a building.”

Courtesy Unity

How does 3D data move into a virtual-reality, augmented-reality (AR), or real-time experience? The forthcoming interoperability between Revit and Unity will allow users to connect, collaborate, create, and deploy immersive, real-time experiences using their models’ CAD data. Unity currently reaches more than 25 platforms spanning the worlds of AR, VR, and mobile.

Courtesy Bevel and Unity

Architect-turned-spatial technologist Logan Smith of Bevel Space, in Portland, Ore., showcased his work in the AU Expo hall. “Right now, we’re helping firms access spatial computing to solve specific pain points in their practice,” Smith says. “But AR and VR are part of a larger trend in technology toward intuitive, intelligent interaction with our data. In our app, there is no button or command to rotate or zoom. You just move the device around like it’s a magic window. That’s a small thing. But over time, we look forward to a much more gestural, human-centered design and construction process. We want Bevel to be a part of that transformation.”

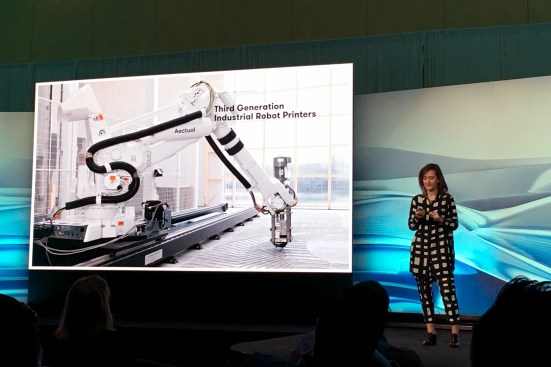

Robotics to Augment Experiences

The session “Automation, Robotics, and Human-Machine Collaboration” featured talks and project examples by Perkins+ Will, Autodesk researchers, and Hedwig Heinsman, co-founder and chief commercial officer of Dutch design office Aectual. Heinsman presented Aectual’s approach to robotically fabricated, mass-customized flooring. She showed examples of 3D printed floors that use bio-based, recycled materials and a terrazzo infill installed at commercial spaces, including Amsterdam Airport Schipol.

Terri Peters

3D printed flooring at the Schiphol airport in the Netherlands by Amsterdam-based Aectual integrates a wayfinding system—and doesn’t require expansion joints due to how the printed terrazzo infill system is fabricated and installed. The company’s work also appears in numerous private residences, temporary installations, and retail interiors.

For Heinsman, the future of work lies in bespoke products and experiences available directly to the consumer that can be ordered online and are made on-demand. Borrowing from advances in robotics and digital manufacturing, the company is developing what Heinsman calls “a growing playlist of architectural elements,” including custom, robotically fabricated staircases, 3D printed façades and interior cladding systems, and mold work for concrete.

The session “From Science Fiction to Fact: The Journey from Speculation to Innovation” focused on how designers might find and test new ideas, curate solutions, and realize them. Architect Tom Van Mele, a researcher from ETH’s Block Research Group, whose super-light and strong 3D sand-printed floor system was showcased in the Expo, spoke about the group’s experimental research project HiLo, an ultra-thin curved concrete roof that uses an innovative cable-net and fabric formwork system that weighs significantly less than traditional formwork. The cable-net and fabric formwork imprints a pattern and texture on the concrete, enhancing the experience for occupants viewing from below.

ETH Zürich / Block Research Group

Block Research Group (BRG) senior scientist and co-director Tom Van Mele, at ETH Zurich, exhibited the HiLo prototype at the AU Expo. The BRG team has 3D sand-printed floor slabs using optimized geometry and innovative materials to be more lightweight, strong, expressive, and beautiful when viewed from below as a ceiling slab. Some of BRG’s work can be seen in its book Beyond Bending: Reimagining Compression Shells (Detail, 2017).

In 2019, the concrete shell will be rebuilt as a rooftop apartment as one of the working prototypes tested at the Next Evolution in Sustainable Technologies house (NEST) in Switzerland. NEST will have 1:1 experiments built on all three levels by different researchers. People will work and live there, testing out the new forms and innovative technologies. The collection of this feedback—and the reconsideration of how a space can work for people and how the performance data can be shared—is an important aspect of the project. We need to see more of this thinking in mainstream building projects to know if and how technology leads to a world that is “better.”

Terri Peters

HiLo, presented by Van Mele, is one of many working prototypes that will be installed in the Next Evolution in Sustainable Technologies house (NEST) in 2019. Located in Dübendorf, Switzerland, NEST will have full-scale component prototypes built by different researchers and people will work and live there. NEST managing director Reta Largo explained: “We want to accelerate the pace of research and amplify the collaborations between research and practice. There is no substitute for building it at full scale and testing it out. That’s how we really accelerate the technology innovation process in the construction sector.”

Afterthoughts

The “Science Fiction to Fact” session also touched on several of the larger issues to which Anagnost had alluded in his keynote. Designers need more than tools—however well-intended they may be. They need the ability to see beyond the AEC industry and grapple with some of the big ideas, such as how the build environment can improve wellbeing and health, advance social equity, and support an aging population; and how designers can incorporate advances in other fields, such as robotics, transport, and artificial intelligence. As it stands, it is hard to know how these new tools and workflows lead to better buildings—and whether architects will even know the impact.

Which brings me to what I would have liked to hear more about at AU: if and how advances made in interpreting and reflecting on design outcomes actually work. I wanted to see a critical evaluation of current evaluation tools, such as Project IQ for BIM 360, which uses artificial intelligence to organize and compare project data—a tool that seem both too futuristic and too limited for the AEC community. Our industry still refuses to share post-occupancy or building performance data across firms, depriving architects of knowledge that could lead to higher performing buildings.

My main takeaway from AU 2018 is that architects should think not only about the use of collaborative tools and workflows now at our disposal, but also what experiences and collaborations these tools can spark. This could truly make the industry “better.”