Drone technology is rapidly expanding into multiple arenas, including videography, delivery, and military applications. One of the most promising applications for flying machines is building construction.

With their relatively small size and aerial movement, drones may at first seem superficial additions to a building site. However, advocates of flying robotic technologies point to the machines’ roles in complementing, not replacing, existing construction processes. Benefits include airlifting lighter materials without the need for cranes, accessing hard-to-reach zones, traversing hazardous locations dangerous for humans, and navigating challenging terrain.

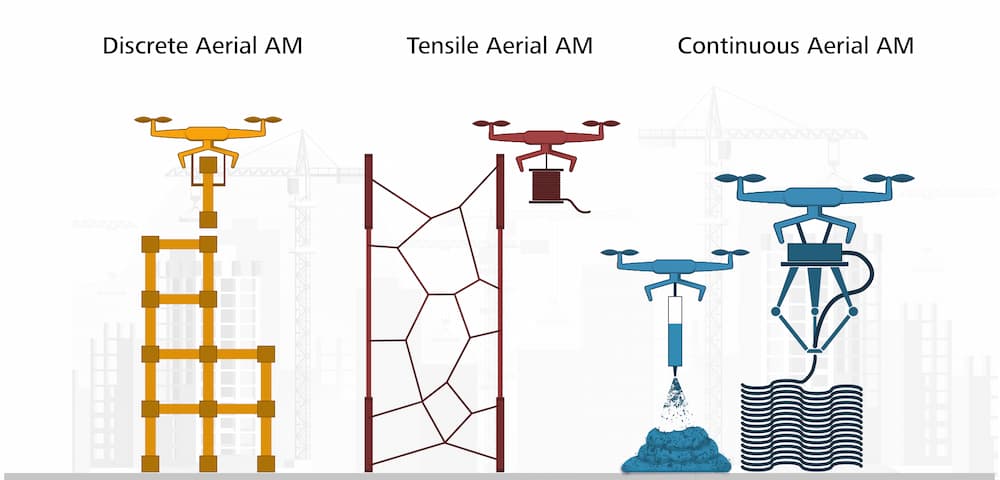

According to the Swiss Federal Laboratories for Materials Science and Technology (Empa), there are three types of Aerial Additive Manufacturing (AAM)—or building via flying robots. Discrete Aerial AM involves modular unit-based construction, Tensile Aerial AM pertains to the construction of tensile-based structures, and Continuous Aerial AM refers to material deposition similar to 3D-printing.

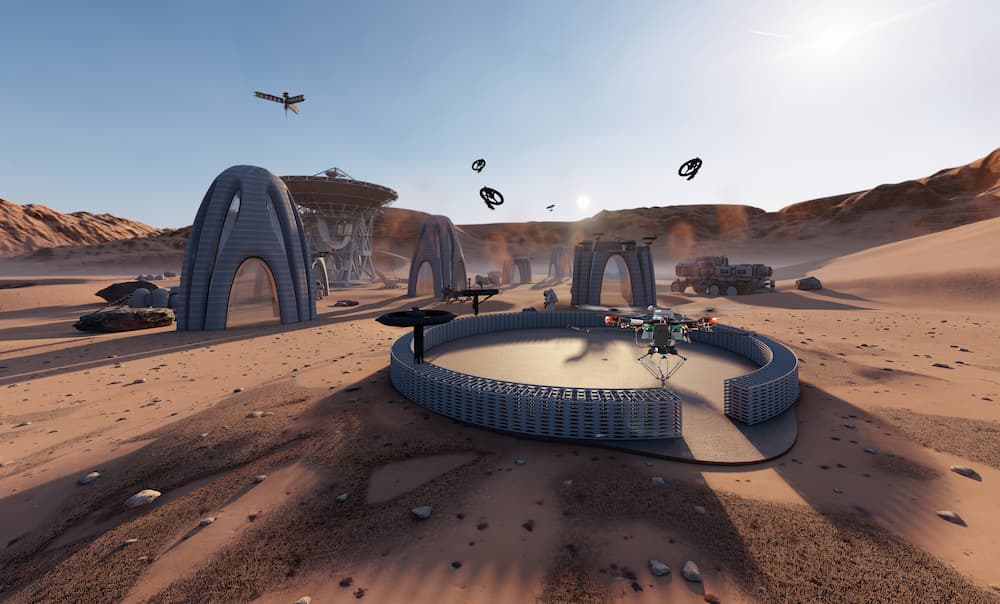

Researchers at Empa and the École Polytechnique Fédérale de Lausanne (EPFL) are investigating the future possibilities of aerial construction in their combined Laboratory of Sustainability Robotics and the Dübendorf-based DroneHub, a test facility for flying robots. The preventative maintenance of existing structures and disaster relief operations are two of the most advantageous applications for AAM.

“Existing robotic systems on the ground often weigh several tons, take a long time to set up and have a limited working radius,” says Sustainability Robotics Laboratory researcher Yusuf Furkan Kaya in an Empa press release. “Construction drones, on the other hand, are light, mobile and flexible—but so far they only exist at low technology readiness levels. They have yet to be used for industrial purposes.”

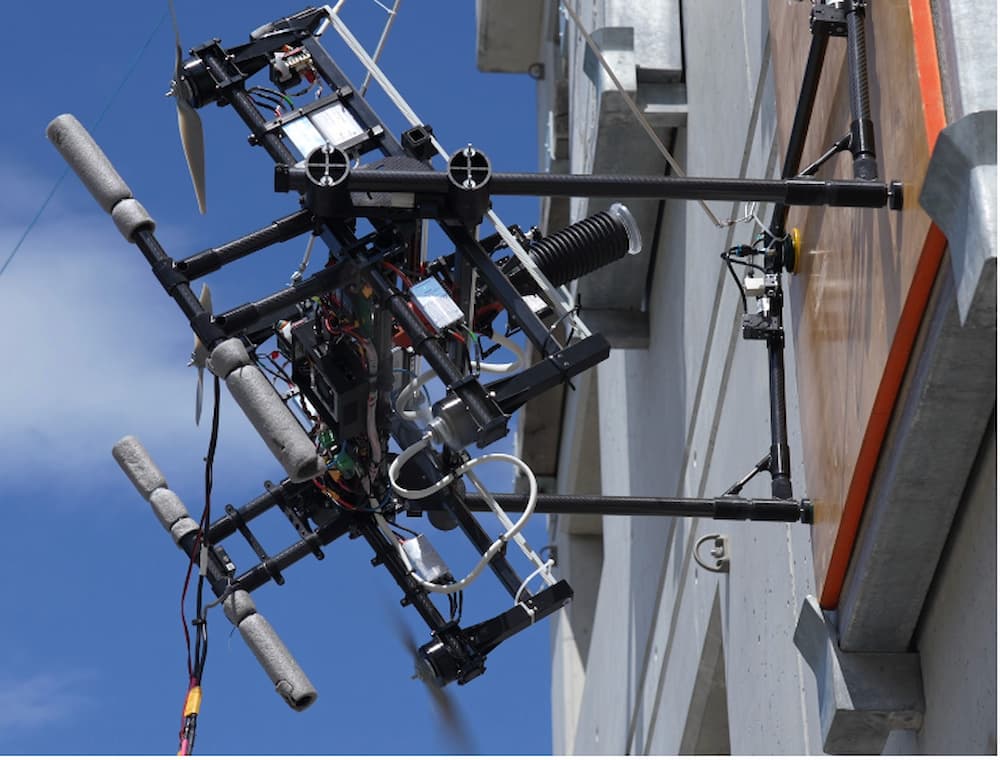

One of the team’s aspirations for the technology is robots that comprehend their environment and materials sufficiently that they can optimize site assessment, supply delivery, and construction. As an example, ETH Zurich researchers have developed a flying robot for building facade assembly.

The article “A perching and tilting aerial robot for precise and versatile power tool work on vertical walls” describes a prototype AAM device that can fly to a targeted spot on a building envelope, fasten itself in place with powerful suction cups, and execute machine operations requiring up to 150N of continuous tool force.

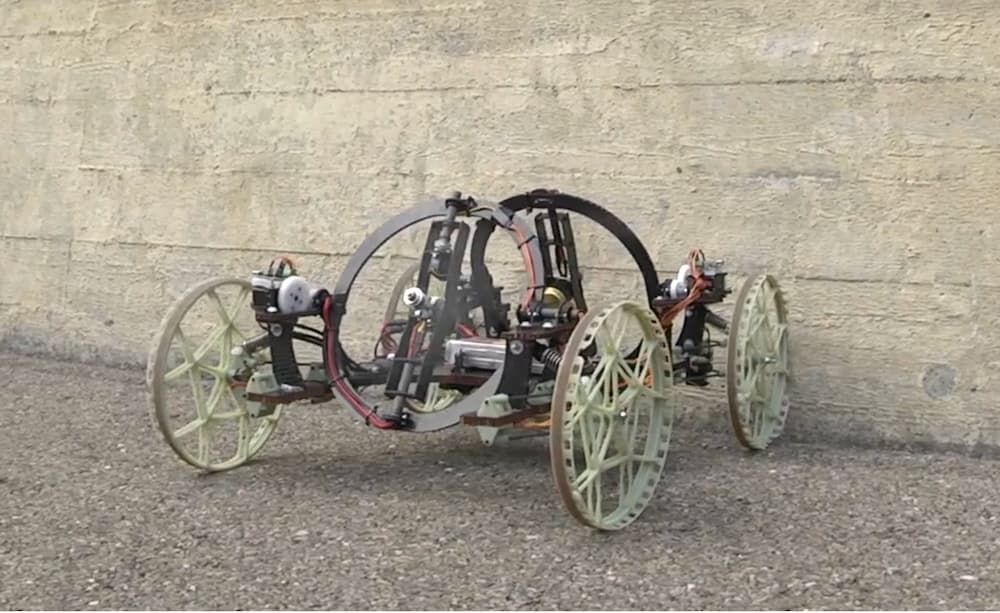

Other emerging robotic technologies offer compelling forms of mobility. For example, the VertiGo, developed by ETH Zurich and Disney Research scientists, is a hybrid machine that can traverse both horizontal and vertical surfaces.

In addition to four wheels, the VertiGo possesses two adjustable propellers that contribute the vertical thrust required for the robot to navigate uneven vertical planes. Two of the wheels are steerable, allowing the lightweight device to navigate with impressive agility. Although the VertiGo is not equipped with tooling capabilities, its versatile mobility offers a compelling platform for future AAM augmentations.

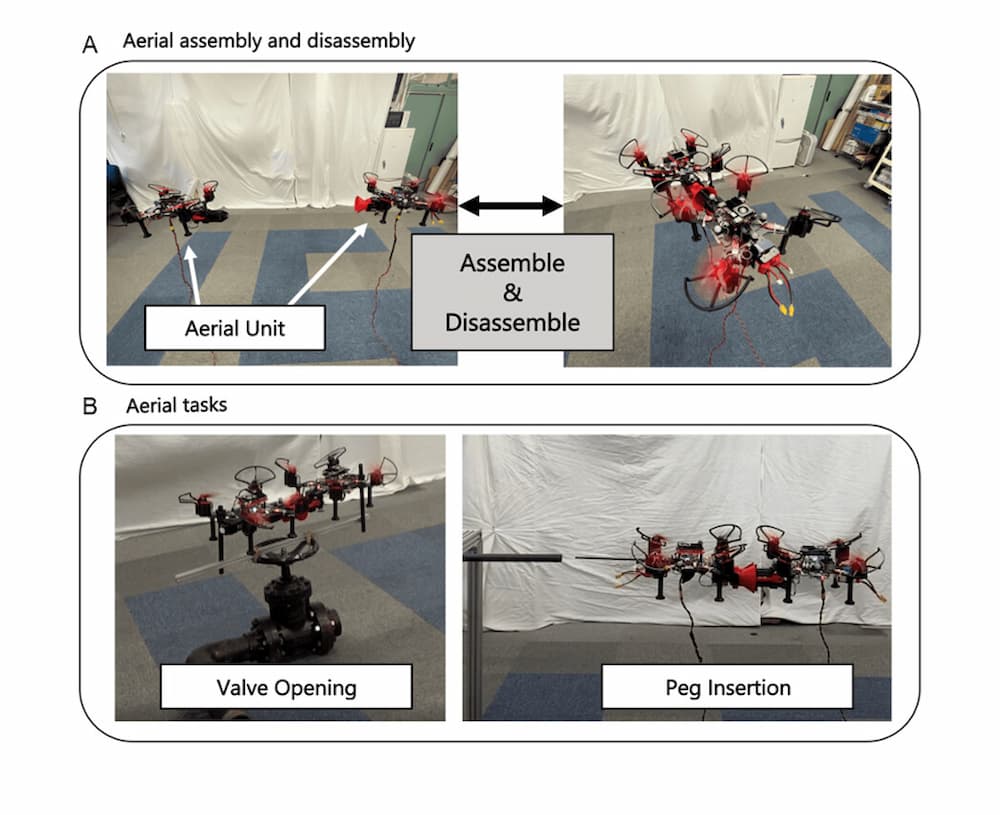

Another robot with angled propellers is the Tilted-Rotor-Equipped Aerial Robot With Autonomous In-Flight Assembly and Disassembly Ability (TRADY), developed by researchers at the University of Tokyo. TRADY’s notable skill is the ability to join with, or separate from, other aerial robots mid-flight. Each device is equipped with a docking mechanism that enables rapid assembly and disassembly. The robots are capable of simple maintenance functions like opening and closing valves, and “pick-and-place” tasks like inserting pegs into pipes. The small machines can navigate tight spaces alone and couple to engage in endeavors requiring more force.

As these various technologies demonstrate, the emerging field of aerial manufacturing reveals a variety of potential capabilities and applications. In addition, ongoing AAM research will exert an influence on the materiality and methods of building construction.

“A drone may be able to fly precisely, but without lightweight, stable and processable materials, it cannot develop its full potential,” explains Mirko Kovac, Head of the Empa and EPFL’s Laboratory of Sustainability Robotics. “And even if both are available, building designs must be adapted to the limited precision of the aerial robots to enable load-bearing structures.”

AAM’s many advantages—including automation, navigation, and worker safety—will encourage the inclusion of more lightweight modular and tensile building components that are optimally suited for drone-built architecture.