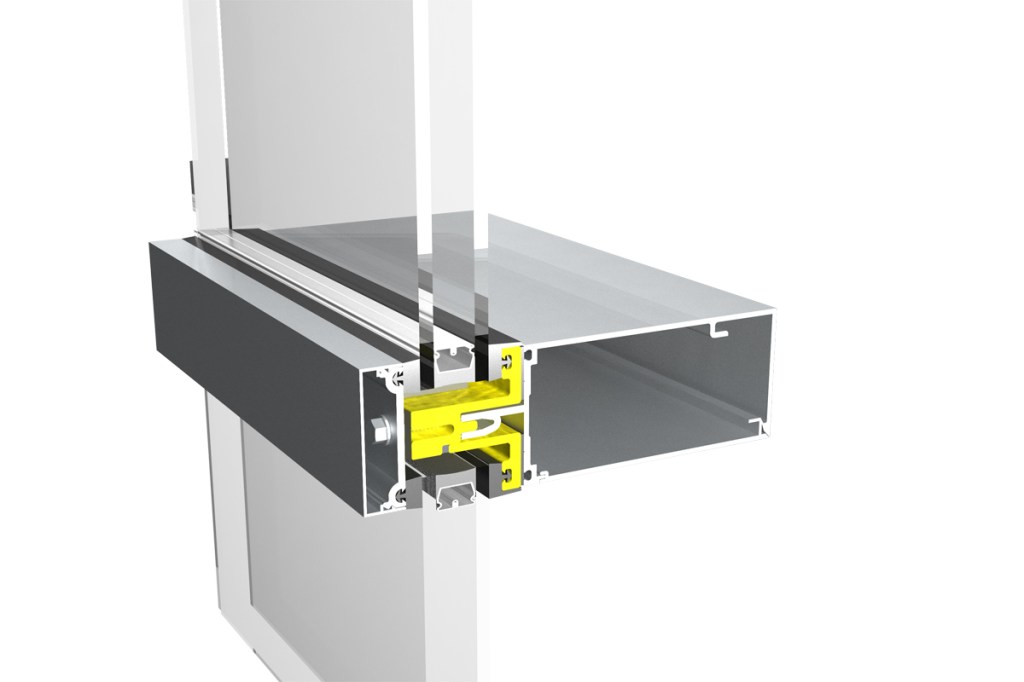

RFF2500 Retro Fit Fiberglass Façade, FreMarq Innovations

When it comes to renovations, architects often have to update existing building elements in order to meet current industry performance standards. Replacing curtainwalls can be costly and time-consuming due to demolition, but Brad Prestbo, AIA, a senior associate at Sasaki’s Watertown, Mass., office recommends a new product by Wausau, Wis.–based FreMarq Innovations. “[RFF2500 Retro-Fit] leaves the existing curtainwall mullions in place by installing a fiberglass pultrusion that can slot over the existing mullion,” he says. “The fiberglass provides a thermal break between the insulating glazing assembly and the highly conductive internal aluminum mullion. This solution reduces cost significantly by no longer requiring replacement of the entire wall.” fremarqinnovations.com

Courtesy HOK

TerraClad Rain Screen, Boston Valley

Combining both form and function, HOK’s New York office incorporated Orchard Park, N.Y.–based manufacturer Boston Valley Terra Cotta’s TerraClad Rain Screen into its design for the University of Buffalo’s Jacobs School of Medicine and Biomedical Sciences in upstate New York. “Key to the design, the material was used in both the façade and the atrium details,” says HOK design principal Kenneth Drucker, FAIA. “To ensure that the building would complement the city’s existing architecture, we wanted a modular system [made] from an organic material. Since terra-cotta is commonly incorporated in many of the city’s significant buildings dating back to the 1920s, it helps seamlessly bridge the old and the new.” bostonvalley.com

Courtesy CannonDesign

Precast Concrete, Gate Precast

CannonDesign’s St. Louis office partnered with Jacksonville, Fla.–based Gate Precast in order to create custom exterior wall molds for Mount Sinai Medical Center’s Emergency Department Expansion and New Surgical Tower in Miami Beach, Fla. CannonDesign vice president Michael Zensen, AIA, says, “[We] used precast concrete to accommodate a curvilinear plan shape, the expressive and modulating wall configurations, hurricane resilience, and construction schedule.” The custom precast forms gave the firm flexibility in design while limiting construction cost. “The fluid expressiveness of concrete with the economy of precast can be an unbeatable combination for creating beautiful, long-lasting forms that enhance the public realm,” Zensen says. gateprecast.com