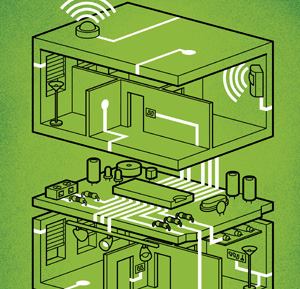

The Future of Lighting Control Systems Most manufacturers of lighting controls agree that as the linking of lighting-control devices to data lines becomes commonplace, building-control systems have come to resemble local-area networks linking PCs. In some businesses, the distinction between the facility management and IT departments has been completely blurred. “We are seeing a lot of facilities people who are actually being tasked with information technology because lighting and HVAC controls are so like IT,” says Cory Vanderpool, business development director for the EnOcean Alliance in North America. “They’re saying, ‘I’ve been told I need to figure out what’s going on with this.’ ”

But connecting lighting control products together on LAN-like networks raises interoperability issues. Specifiers and installers wish for lighting controls to connect seamlessly, and they don’t want to be beholden to a single supplier for components. “I no longer think of controls for things like lighting or automatic blinds as separate systems, even if they are provided by different manufacturers and installed by different contractors,” says Russell Fortmeyer, a senior sustainability consultant in Arup’s Los Angeles office who also has a background in electrical engineering.

Most manufacturers of lighting controls consider it an advantage to be able to work with many players. “We actually have many integrated partners,” says Crestron’s Bramley. “They include Honeywell, Siemens, Johnson Controls, Trane, Carrier, and many others. We work on open protocols and play well with others.”

Solid-state lighting is already dramatically altering standard specification practices. But where the dimming of LEDs is concerned, the technical challenges are anything but straightforward. Many LED driver technologies are in use and there are few standards.

Yet combining the products of more than one company always has the potential to create complicated set-up and programming issues. “We started out trying to work with other manufactures’ magnetic dimming ballasts, which did not operate consistently with our controls,” Lutron’s Lind says. “We believe that systems in which Lutron is the provider of all of the key components offer the highest reliability and provide a clear ‘owner’ to be responsible for the performance of those systems. Systems that are interoperable and scalable are most desirable, but there is some debate about what it means to be an open source provider. All manufacturers, including Lutron, have some level of proprietary functionality in their system infrastructure. Lutron can work with open protocols such as zero-to-10V Analog Control Protocol, DALI, and BACnet, and does quite often.”

Lighting Controls for the Future More than one of the manufacturers we spoke with mentioned that solid-state lighting is already dramatically altering standard specification practices. But where the dimming of LEDs is concerned, the technical challenges are anything but straightforward. Many LED driver technologies are in use and there are few standards. Glenn Garbowicz, general manager of the Thomas Research Products division of Hubbell Lighting, which manufactures LED drivers says, “There are many issues of incompatibility out there. You have to be careful what you’re getting into.”

Benya and Fortmeyer believe that the big winners in the years ahead will be the ones that make lighting components easy to use, and that, while HVAC controls are getting more complicated, lighting controls are getting simpler. “It’s not too far into the future when people are going to be able to plug-and-play a lighting network,” Benya says. “It used to be that when you put in a ballast to control [the lighting] you had to look up dip-switch settings in a table. Now, I can put in a new programmable ballast, figure out its address and location, [and] type it into a database—and it took me as long to do that as it did to say it.”

Lighting Controls Market ForecastAccording to a March 2011 report by Pike Research, a market research and consulting firm that provides in-depth analysis of global clean technology markets, the intelligent lighting controls market is seeing strong growth. The forecasters predict that the global lighting controls market will increase from $1.3 billion to $2.6 billion by 2016. Aggressive forecast models for the same time period predict a market of $3.5 billion. Initiatives to reduce energy consumption, bring more natural light into the workplace, and provide individuals with greater lighting control are contributing factors in the increased awareness of lighting control systems, products, and market demand. |

Fortmeyer agrees with this assessment and also foresees that hard-wired controls will be superseded. “These devices can all generally be reduced to IP addresses, at which point I don’t really care where they are or how they plug into the system. Eventually, we won’t have to plug anything in and will transmit control signals wirelessly. That has huge implications for existing buildings, where the cable backbone may be nonexistent, out of date, or simply too expensive to retrofit. That will really help in projects that require intense coordination, like a hospital, where sensitive controls and IT cables have to be carefully routed to avoid interference.”

“If you ask building management systems companies where they are heading, it’s all about nanotechnology and reducing sensors and control points down to microscopic scale,” says Fortmeyer. “In 20 years, sensors will be so small and so cheap, you will just spray them on any surface by the thousands. For example, your desktop could tell you the exact lumens hitting its surface, and that could be relayed to automatically dim your lighting until the right balance was struck.” This would also allow sensors to be put into a building’s envelope so that the building could sense thermal loads or sunlight, and automatically change blinds or the perimeter lighting.

The Greatest Challenge and Promise In the near term, Benya says, easily installed products could be put into existing buildings right now, but the localities adopting laws that mandate stringent codes for new buildings are so far letting existing buildings slide. And yet that’s where the greatest potential for saving energy lies. “For every new building we build that is energy efficient we have to retrofit 1,000 buildings that are built,” he notes. “The difference is going to be in the thousand, not in the one.”

Charles Linn is a New York–based journalist and editor. He has been writing about architecture and lighting technology for the past 25 years.