Tim Hursley

Broken glass to be recycled piles up at the mixing or "batching"…

1) Batching At Carlisle, two identical glassmaking lines unfold side by side within the plant’s enormous shed, which runs one-third of a mile long. Although the plant employs about 525 people, you don’t see a lot of them standing around these lines, not least because, in some spots, the heat from the furnaces is so intense that you feel as if your face might peel off. For the most part, the human hand is at work inside air-conditioned control consoles, monitoring computer screens and closed-circuit cameras that track the flow of glass along an exquisitely automated path.

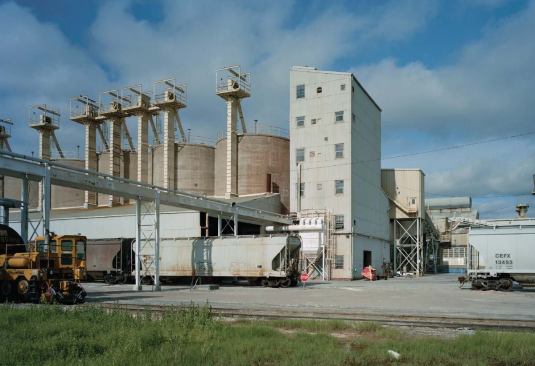

The first stage, batching, prepares the raw materials for melting in the furnace. A battery of six enormous concrete silos stands just outside the front end of the plant, filled with raw materials that arrive by truck or train: sand, dolomite, and a mixture of soda ash and salt cake. Often added to these ingredients are recyclable glass shards or “cullet,” much of which comes from the plant’s finishing end.

Glass consists mostly of sand. At PPG it comprises about 70 percent Oriskany sand, an amazingly pure white substance quarried in northern Virginia and West Virginia. PPG prizes Oriskany sand for its low iron and chromium (iron, for one, gives glass a greenish hue) and high silica content, which makes for an exceedingly clear product.

From the minute the materials arrive, they are in nearly constant motion. Inside the gray, dusty confines of the silo compound, a long, flat conveyor takes the materials in sequenced layers from their silos and sends them to a bucket elevator that carries them up to a scale to check their combined weight. They fall into a mixer that stirs them together “like an old ice cream bucket,” Kapura says. The mix is basically damp sand as it rolls across a high bridge conveyor to the main plant and into a hopper that feeds the furnace.

2) Melting and Fining

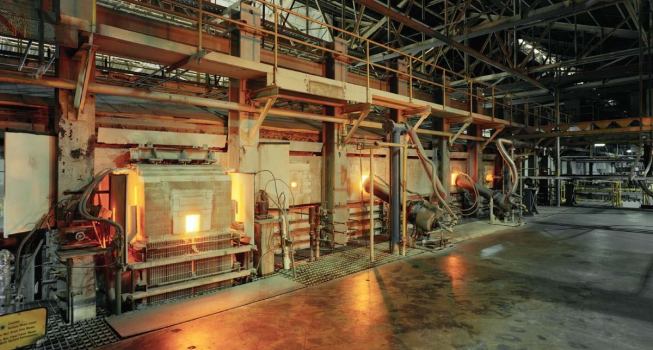

Two enormous melting furnaces stand side by side at the head of the plant, radiating prodigious amounts of heat. The yellow-painted iron handrails of a nearby stair are hot to the touch. Silica melts at about 3,000 degrees Fahrenheit—the peak temperature inside the furnace—although adding soda ash and salt cake helps lower the silica’s melting point. Through the melter’s open end, you can see the material mixture entering its white-hot confines.

The melter, properly known as a Siemens Side Port Regenerative Furnace, has a tank a couple of feet deep and 200 feet long to hold molten material. “You could swim in there,” Kapura says, “if you didn’t burn up first.” The tank is surrounded by four sets, two on each side, of 36-foot-high regenerators, so called because they force hot air into the furnace and ignite a series of natural-gas flames over the top of the glowing melt, then take back the excess heat for reuse.

Once the mixture is melted into liquid glass, it travels to a second large tank, the refiner, for what is called fining. At this point, when chemical reactions among the batch materials are taking place, the glass is suffused with air bubbles, which are no good for glass. So more air bubbles are pumped in—to bind with the existing bubbles and force them out.

The refiner also serves to cool the glass to about 2,000 F to reach its correct viscosity before it is formed. Above that temperature, Kapura explains, the glass is too much like water for forming, and below that, it’s like—what else?—molasses.