Project Description

The Saltatur demonstrates innovative research in the design and fabrication of a prefab, discrete, spatial composite structure consisting of a spatial, compression-only concrete body, post-tensioning steel rods, and an ultra-thin glass structure on its top in the form of long-span furniture. Using discrete spatial systems would minimize the volume of concrete and the carbon footprint while preserving the necessary mass for structural performance and specific architectural detailing. Achieving a high level of efficiency in utilizing concrete for spatial systems requires a robust and powerful structural design and fabrication approach.

There are multiple design innovations in various phases of the realization of this project, from conceptual structural design to fabrication. The structural form of the project was developed using 3D/polyhedral graphic statics with a very particular control over the magnitude of the horizontal forces in the system. As a result, the entire concrete body of the structure is held in compression by the tension ties at the top and bottom of the structure with no horizontal reactions at the supports.

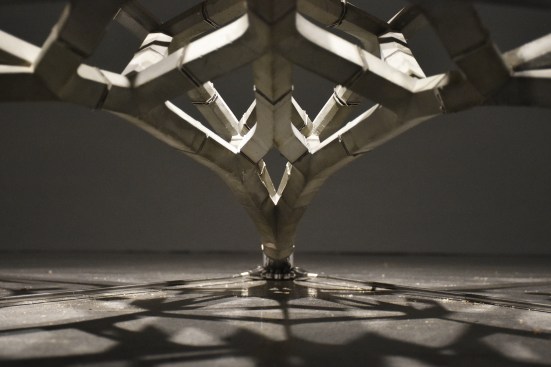

A node-based assembly was considered as a method of construction. An innovative detailing was developed that allowed fixing members in their exact locations in 3D avoiding any spatial collision of the branches during the assembly. Although the concrete structure has been designed to act in pure compression, some of the members will experience tensile stress in the cases of asymmetric loads, especially during the assembly process. The proposed bespoke steel connection transfers the tensile force between the concrete members effectively.

The ultra-thin (4mm) glass structure on the top was slumped formed into a funicular geometry with discrete parts spanning 3.75 meters. The glass can carry the applied loads as a three-hinged discrete arch with particular detail connections preventing the horizontal movements of the glass parts.