Project Description

This article appeared in the November 2019 issue of ARCHITECT as part of our expanded coverage of the 2019 AIA COTE Top Ten Awards.

By providing 56% of needed potable water through on-site water management (and other green bona fides) this education center teaches visitors as much about sustainability as it does about flora and fauna.

From the beginning, says Opsis Architecture founding partner Alec Holser, AIA, the program for the Oregon Zoo Education Center informed the design team’s approach: “Its mission is all about education, so the building became a platform for delivering a message around climate change, habitat preservation, and other issues.”

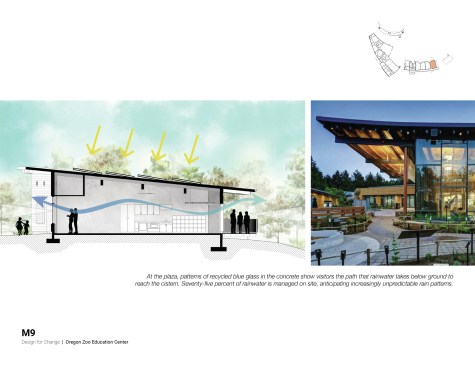

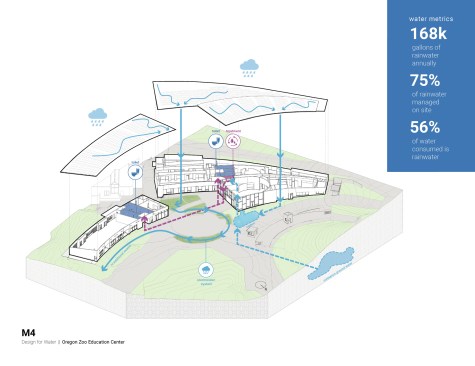

That meant making the center—which is actually two buildings, an exhibit wing and a classroom wing—as sustainable as possible. One obvious place to look for efficiencies in Portland, which has an annual rainfall of 43 inches, or 11 inches above the national average, is water. Fully 75% of the rainwater that falls on the site is managed, either by directing it through a series of rain gardens and bioswales, or—if it falls on the roof of the classroom building—by funneling it into a 10,000-gallon cistern that is topped off by water from an underutilized aquifer beneath the zoo. As a result, rainwater supplies 56% of the water consumed on-site—largely for use in the building’s toilets, which double as the primary restroom facility on the west side of the zoo.

But reducing water consumption is only part of the equation for a truly sustainable structure. To minimize energy use, the center utilizes an air-source heat pump with variable refrigerant flow technology, which allows for localized heating and cooling. Classrooms are fitted with garage-door-like windows, so that in the summer the facility can take advantage of natural ventilation (a red light/green light display next to each window tells users when it is appropriate to open them).

As a result of these strategies—and others such as rooftop photovoltaic cells—Opsis expects the building to be carbon positive, keeping 1.9 pounds of carbon per square foot out of the atmosphere every year.

Opsis didn’t stop at making the building sustainable, they also embraced the mandate to make it didactic. “The zoo decided the center’s theme is ‘small things matter,’ ” Holser says. So the architects asked themselves: “What are the things we can demonstrate through this building?”

Before getting into any specific features, Opsis wanted to make sure the building didn’t project a pessimistic message about the planet’s varied environmental threats. “Some of these challenges today are so overwhelming,” Holser says. “And because of that, it needs to be a receptive, welcoming, joyful building.” Opsis achieved that by blurring the lines between inside and outside—spiraling the two buildings (and an adjacent train station that provides visitors with access to other areas of the zoo) around a central plaza. The arrangement has the effect of encouraging visitors to explore different corners of the facility. Children will find a variety of permanent and rotating exhibits, from nature demonstrations to an insect zoo. For adults, especially those with green thumbs, the Wildlife Garden, an ongoing demonstration project, teaches sustainable lawn and garden skills they can apply at home.

Another outdoor feature, the Turtle Lab, lets visitors watch baby western pond turtles from birth to maturity, after which the animals are released into their natural habitat—a program that demonstrates the zoo’s role in promoting the region’s threatened species. Helping to direct all this is a full-time official from the U.S. Fish and Wildlife Service—in fact, the Oregon Zoo is one of the only zoos in the country to have one.

Above all, Holser says, Opsis strove to encourage visitor curiosity and learning by making the center’s sustainable design strategies—like the solar panels on the roof of the train station or the rain gardens that filter stormwater—visible to the public. “When they can see it, that encourages people to ask, ‘What’s that about?’ ” Minor details, perhaps—but like the center’s mantra states, small things matter.

Project Attributes

Architect: Opsis Architecture

Owner: Metro

Location: Portland, Ore.

Project Site: Previously developed land

Building Program Type(s): Education—General

Year of Design Completion: 2016

Year of Substantial Project Completion: 2017

Gross Conditioned Floor Area: 19,000 square feet

Gross Unconditioned Floor Area: Zero

Number of Stories: One

Project Climate Zone: ASHRAE 4C

Annual Hours of Operation: 2,920

Site Area: 83,000 square feet

Project Site Context/Setting: Suburban

Cost of Construction, Excluding Furnishings: $18.7 million

Number of Residents, Occupants, and Visitors: 1.6 million

Project Credits

Project: Oregon Zoo Education Center, Portland, Ore.

Client/Owner: Metro

Design Architect: Opsis Architecture, Portland, Ore. . Alec Holser, AIA (partner, principal-in-charge); Paul Kinley, AIA (partner); Steven Nelsen, AIA (associate principal, project manager); Jennifer Cambier, AIA (associate principal, project architect); Jeri Tess (associate principal, lead interior designer); Heather DeGrella, AIA (sustainability design leader); Angela Alexander (interior designer); Chester Morgan, AIA (architect)

Zoo Design/Insect Zoo Architect/Landscape Architect: Jones and Jones Architects and Landscape Architects

Interior Designer: Opsis Architecture

Structural Engineer: Catena Consulting Engineers

MEP Engineer: PAE Engineers

Civil Engineer: KPFF Consulting Engineers

Geotechnical Engineer: Geotechnical Resources, Inc.

Construction Manager/General Contractor: Fortis Construction

Lighting Designer: Luma Lighting Design

Exhibit Consultant: Work as Play

Exhibit Consultant: IQ Magic

Cost Consultant: ACC Cost Consultants

Food Consultant: Halliday Associates

Surveyor: Westlake Consultants

Code Consultant: Code Unlimited

Acoustics: Listen Acoustics

Sculptural Artist: Rob Ley Studio

Size: 20,000 square feet

Cost: $18.7 million

Materials and Sources

Acoustical System: GTS Interior Supply; Jasco; OSI; Owens Corning Adhesives/Coatings/Sealants: Tremco; Conseal; KorNSeal; CertainTeed; NWCB NW Wall & Ceiling Bureau

Appliances: The Modern Fan; Summit Appliance; GE; Asko; Hobart; Traulsen; Electrolux; Vollrath; Vitamix; Turbochef; Manitowoc; Pentair; Structural Concepts; Tomlinson; Pacific Stainless Products

Carpet: Interface

Ceilings: 9 Wood

Concrete: CalPortland; Ash Grove Cement Co.; Master Builders; Grace Construction; Ross island Sand & Gravel Co.; Advanced Floor Products

Fabrics/Finishes/Hardware: Faustrollean Fixture Co.; Salice America; Olympus Lock; Häfele; Woodwork Institute; Accuride International; ADA Toe Kick; Pental Quartz; Pagh Custom Woodworking; Cabot Stain; Grip-Rite; Knoll Textiles; Hilti; Rotofast; States Industries; DalTile; Designtex Flooring: Duro Design; Floor Solutions; Johnsonite; T&A Supply Co.; XL Brands; Schluter Systems; Construction Specialties

Furniture: Building Material Specialties; Legacy Lockers

Glass: Window Tech; Raynor

Gypsum: Georgia Pacific

HVAC: King Electric Manufacturing Co.; General Sheet Metal; Johnson Barrow Oregon; LG; Greenheck; Aaon; Aspen Pumps; Tek-Air Systems; Yaskawa America; RenewAire; Price Industries; Air Concepts; Ruskin; Design Polymerics; Berry Plastics; Thermaflex; J.L. Wingert Co.; U.S. Water Services; Mueller Streamline Co.; Uponor; Elo Touch Solutions; Delta Connects; BAPI Building Automation Products; Flowline; Ebtron; Veris Industries; Belimo; Functional Devices; Mason Industries; CEAS Construction Engineered Attachment Solutions; Spirotherm

Insulation: Coravent; Knauf Insulation; Thermafiber; RMax; Temco; RectorSeal

Lighting: Moooi; Solus; Prescolite; Lucifer Lighting; Ligman Lighting USA; Wila Lighting; Cascade Lighting Representatives; Vode Lighting; Kurtzon Lighting; Juno Lighting; Focal Point; Prudential Ltg.; Cooper Lighting; Selux Corp.; B-K Lighting; Eaton; Interlux; EldoLED; Harry L Stearns; Bruck Lighting

Lighting Control Systems: Acuity Controls; Lutron; Volt Lighting Group; ROAL Electronics; Bayco; Leviton Manufacturing Co.; AFC Cable Systems; Cerro Wire; Service Wire Co.; Allied Electrical Group; ANAMET Electrical; Hubbel Co.; Legrand Wiremold; Legrand Wattstopper; Carlon; Schneider Electric

Masonry/Stone: Willamette Graystone; CalPortland; Northwest Masonry Restoration Co.; Carlson Testing; Spec Mix; Quikrete-Northwest; Knife River Corp.; K&M Rebar

Metal: K&M Rebar; TT&L Metal; Matrix Industries; TPlus Steel Fabricators

Millwork: Legend Custom Woodworking; Pagh Custom Woodworking; Old Country Millwork

Paints/Finishes: PPG; Sikkens Wood Finishes; Rudd Co.

Photovoltaics/Other Renewables: SolarWorld; Astrodyne TDI; UNIRAC; Quick Mount PV; Enphase Energy

Plumbing/Water System: Encore Plumbing; Victaulic; Gast Manufacturing; Viking; Afcon; ITW Buildex; Anvil International; Ferguson Enterprises; Zurn Industries; Sloan Valve; Jay R. Smith MFG Co., distributed by Acudor/Acorn; Hold Rite; Grundfos; Watts; PPP Precision Plumbing Products; Kohler; Chicago Faucets; McGuire Manufacturing Co.; Elkay; Delta; T&S Brass and Bronze Works; Leonard Water Temperature Controls; Reelcraft; Bemis Manufacturing Co.; American Standard; AO Smith; Streamline distributed by Mueller Streamline Co.; Cerrotube Flow Products; Elkhart Products Corp.; Rocky Mountain Colby

Canplas; Charlotte Pipe and Foundry Co.; Olympic Foundry; FlowTherm Systems; Mueller Systems; Wessels Co.; Atlantic Ultraviolet Corp.; FSI; Bell & Gossett; Sensus; Orenco; Xerxes Corp.

Roofing: Snyder; Carlisle; Analytical Laboratory Services; Johns Manville; Apollo Valves; Trerice; Nystrom

Site/Landscape Products: Urban Accessories; D&L Supply Co.; Ash Grove Cement Co.; Lane International Corp.; Oldcastle Infrastructure; Sunmark Seeds International; Baker Rock Resources; Hydrotech; 3M Electrical Products Division; Weld On; Paige; Rainbird; Matco-Norca; Lasco Fittings; Hanover Architectural Products; Reliable Automatic Sprinkler Co.; Nibco; GSE Environmental; Columbia Green Technologies; T&L Nursery; Loen Nursery; Trillium Gardens; Teufel Holly Farm; California Direct-OR Grown; Champoeg Nursery; Seven Oaks Nursery; Blooming Nursery; Sebright Gardens; Watershed Gardenworks; Fisher Farms; William Dillard; Mahonia Nursery; Northwest Shade Trees; Blue Heron Farm; Chrishaven Trees; Teuful Roy Farm; DeWildes’s Wholesale; Hines of Oregon; Bradshaw Nursery; Rocky Mt. Nursery; Briggs Nursery; Xera Plants; Joy Creek Nursery; J Frank Schmidt; Youngblood Nursery; Western Laboratories; Fibar; Typar Landscape

Structural System: Portland Fasteners and Construction Supply; Simpson Strong Tie; RedBuilt; Critical Structures; Eaton; Architectural Woodwork; Cudahy Lumber Co.; El Creek Forest Products; Roseburg Forest Products; Interfor

Walls: TPlus Steel Fabricators

Wayfinding: Meyer Signs; Formations

Windows/Curtainwalls/Doors/Cabinets: Faustrollean Fixture Co.; Bell Hardware of Portland; Wayne Dalton Overhead Doors

Activar; Eggers Industries; EZY Jamb; Rockwood Manufacturing Co.; Stiles; Budget Blinds; Draper; Mermet; Phifer

Specialties/Miscellaneous: Wolmanized; Velux; Curtis Restaurant Equipment; Pacific Stainless Products; Custom Building Products; W.H. Cress Company; Koala Kare Products; Bobrick; IPC; Kwik-Wall; Scranton Products; Building Materials Specialties; Cambro Manufacturing Co.; Metro; Advance Tabco; Gaylord Ventilation; Guardian Fall Protection; Johnson Controls; Simplex; GB Manchester; Mohawk Cable; Panduit; Onssi; Axis Communications

This project is a winner in the 2019 AIA COTE Top 10 Awards

FROM AIA:

Inspiring visitors to engage in sustainable actions is the mission of the design and exhibits at the Oregon Zoo’s Education Center. The center—the fifth project funded by the zoo bond—provides a home base for thousands of children who participate in camps and classes annually and serves as a regional hub, expanding the zoo's youth programs through collaborations with U.S. Fish and Wildlife and other partners.

The center includes classrooms, meeting spaces, gardens, and a Nature Exploration Station (NESt), inspiring visitors to get outside, learn about nature, and take action on behalf of nature. Illustrating that “Small Things Matter,” the zoo provides its 1.7 million annual visitors with interactive exhibits that demonstrate how actions can help maintain a healthy planet. The center creates dialogue between the built and natural environment, with each interior space offering a corresponding visible and connected outdoor space. The wood and steel woven structure of the NESt is inspired by the nests of animals creating shelter and order in the environment. The NESt is the center of activity that visitors access through large sliding doors. They learn the stories of local conservation heroes and access the turtle conservation lab and the Insect Zoo—where the smallest of animals can have the largest ecosystem impacts. Within a plaza at the west end of the zoo, the tight, irregular site has curving boundaries of exhibits, the zoo railway, a pedestrian path, and a steep south hillside. The building hugs the central plaza, and learning landscapes exist throughout. Inspired by the unique spiral patterns prevalent in natural systems, two curved roofs welcome visitors to the plaza. Sustainable elements, including solar panels, native plants, bird-safe windows, and rain gardens, are designed to educate the public. The center recently earned LEED Platinum certification with 82 points and Portland AIA’s 2030 COTE award.

Metrics Snapshot

Community engagement: A partnership was formed with stakeholders to share in the decision-making process including development of alternatives and identification of the preferred solution.

Walk score: 33

Estimated occupants who commute via alternative transportation (biking, walking, mass transit): 31.1 percent; A 2015 Zoo Employee survey for all staff showed that 60 percent drove alone, 8.4 percent carpooled/vanpooled, 23.4 percent took transit, 7.5 percent biked, 0.2 percent walked and 0.3 percent had a compressed workweek. Of the 182 employees there was a 76 percent response rate. A 2015 visitor transportation survey showed that 80 percent drove, 19 percent took transit, 1 percent biked, 0 percent walked and 0.5 percent responded “other”. The survey demographic included visitors to the zoo and other public attractions nearby. Annual carbon emissions were not determined for either survey.

Percentage of the site area designed to support vegetation: 40

Percentage of site area supporting vegetation before project began: 41

Percentage of landscaped areas covered by native or climate appropriate plants supporting native or migratory animals: 100

Predicted annual consumption of potable water for all uses, excluding process water: Indoor water use: 322 kGal/year, 56 percent reduction from federal standards

Is potable water used for irrigation? yes

Predicted peak month consumption of potable water for outdoor (irrigation) purposes: 0.17 gallons/sf

Actual annual consumption of potable water for all uses: 208,186 gallons

What percentage of water consumed onsite comes from rainwater capture? 58

Is greywater or blackwater captured for re-use? no

Percent of rainwater that can be managed on site: 75

Water quality for any stormwater leaving the site: 84 percent of TSS removed from stormwater runoff

Cost per square foot: $350

Estimated annual operating cost reduction (identify baseline): 105.5 percent savings, as compared to ASHRAE 90.1-2007

Predicted consumed energy use intensity (EUI): 42 kBtu/sq ft/yr

Predicted Net EUI: -4.3 kBtu/sq ft/yr

Predicted Net carbon emissions: -1.9 lb/sq ft/yr

Predicted reduction from national average EUI for building type: 107 percent

Predicted lighting power density: 0.56 W/sq ft

Actual Consumed Energy Use Intensity (Site EUI): Three meters that track solar production are not accurately metering energy production due to installation issues with wiring and control devices Tracking of energy production/use is on hold until the issues are resolved. Troubleshooting is currently underway, and once the meters are corrected tracking will resume as planned.

Percentage of floor area or percentage of occupant work stations with direct views of the outdoors: 95 percent

Percentage of floor area or percentage of occupant work stations within 30 feet of operable windows: 56 percent

Percentage of floor area or percentage of occupant work stations achieving adequate light levels without the use of artificial lighting: 92 percent >300 lux at 3pm March 21

Is this project a workplace? yes

How many occupants per thermal zone or thermostat: Occupants per thermal zone vary depending on the space. For the office spaces, the design populations included: YCO and Zap office (6 people); Uno office (3 people); Workroom (8 people); and Teen (15 people).

Percentage of occupants who can control their own light levels: 100 percent

Peak measured CO₂ levels during full occupancy: CO₂ is measured and controlled in all multi-occupant spaces. The dedicated outside air units are sized to deliver 30 percent more than the code required outdoor air volume and are controlled to maintain less than 1000 ppm in the zones.

Peak measured VOC levels during full occupancy: VOCs are not measured. However, the buildings were flushed in accordance with the LEED credit. And again, the dedicated outside air units are sized to deliver 30 percent more than the code required outdoor air volume.

CO₂ intensity: 53.26 lbs/sf

Estimated carbon emissions associated with building construction: 53.26 lbs/sf

LCA: Were other life-cycle assessments (LCAs) conducted? no

EPD: Were environmental product declarations (EPDs) collected? no

Percentage (by weight) of construction waste diverted from landfill: 98 percent

Did you calculate the percentage of materials reused from existing buildings or other local sources by weight? Percentage not tracked, but several materials were reused from onsite:

- The pavers at the backyard habitat were salvaged from the old Elephant Plaza picnic area (375sf and 10,000lbs)

- Logs in the nature play area were salvaged from onsite, approximately 1,200lbs total.

- The landscape gates and Wildlife Garden Shelter were built out of wood salvaged from the decommissioned Elephant Museum.

- On the public facing exterior wall of the center is “The Continuity of Life Forms,” a large scale mid-century modern mosaic by renowned Portland artist, Willard Martin. This iconic piece had stood on the same site for more than 50 years. It is returned to this location as a way of preserving part of the Zoo’s history and creating a gateway experience.

Did you calculate the percentage of materials reused from existing buildings or other local sources by volume? no

Did you calculate the percentage of materials reused from existing buildings or other local sources by cost?

- Percentage of recycled content of building materials (by cost): 15 percent

- Percentage (by cost) of the project materials extracted and manufactured regionally (specify distance): 32 percent

Percentage of project floor area, if any, that represents adapting existing buildings: 0 percent

Anticipated number of days the project can maintain function without utility power: 0 days; the PV array is tied to the grid so electricity would not be available, but the buildings are designed with passive strategies for ventilation.

Percentage of power needs supportable by onsite power generation: 100 percent

Carbon emissions saved through adaptive reuse vs new construction: 0 percent

Resilience rating system metrics: We were guided by the Resilient Design Institute’s resilient design principles and strategies. The education center meets the Resilient Design Institute’s standard for non-potable water (2-3 toilet flushes per person per day using the captured rainwater from a local annually replenished groundwater source. Passive survivability standards (an acceptable low and high temperature of 55 and 85 degrees are also met using passive ventilation strategies.)

Post-occupancy evaluation summary: A POE conducted in the winter of 2018 surveyed the building's wide range of occupants (education center, camp, teen program, food service, catering, animal care and program staff, and partners) in an array of areas. Many core principles of the building design received positive responses: the building design was incorporated into the curriculum and students ask questions about the purple bathroom fixture handles, the bird friendly glass and the solar panels viewable through a telescope. 100 percent felt that the building successfully connected them to the outdoors, 87 percent were satisfied with the temperature of their workspace, and 86 percent were satisfied with the air quality. The Teen Program space was noted as a comfortable and welcoming home for the Teen Program. The survey indicated the overhead doors and windows were not being used as often as they could be for passive ventilation. In the classrooms, 84 percent of surveyed occupants reported they understood the green light operating system, but 39 percent reported never opening the windows. The insect zoo was reported to overheat when it got crowded in summer months. These are areas that will be explored with the building operations team as the Education Center goes into its second full year of use.