This post is part of a monthly series that explores the historical applications of building materials and systems through resources from the Building Technology Heritage Library (BTHL), an online collection of AEC catalogs, brochures, trade publications, and more. The BTHL is a project of the Association for Preservation Technology, an international building preservation organization. Read more about the archive here.

While the tin ceiling has enhanced interiors since the 1880s, historically, they were marketed as steel ceilings—and contained no tin at all. Also advertised for its design, economy, and fire resistance, these “tin” ceilings became a prominent commercial interior adornment in the early 20th century.

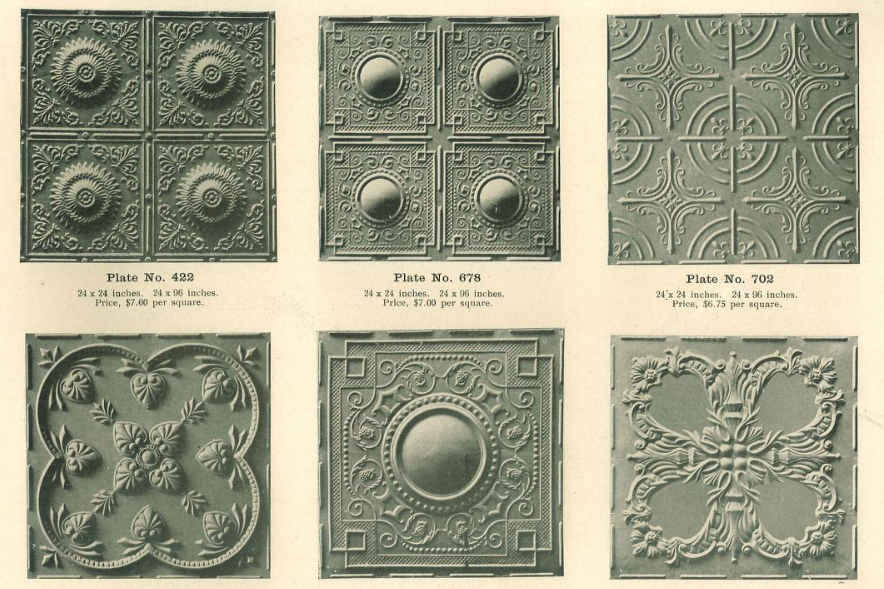

Manufactured through the 1940s, the ceiling tiles were often made of stamped, 26-gauge metal panels and came in a range of sizes, from 2- to 8-foot modules. They were usually left unfinished to be painted on site. The panels were nailed to a system of wood furring strips that could be installed over an existing plaster ceiling, making the material equally adaptable for new construction or renovation projects, which often coincided with the electrification of buildings during this time. The metal ceiling—typically painted in light colors—was a cost-efficient and attractive way to redecorate an interior after an electrician finished installing new wiring in the joist cavity.

The tile systems were designed with overlapping uniform panels for the main ceiling, with an edge “filler” panel that could be trimmed to make up for any irregularities in interior dimensions. Cornice systems and beam covers were also offered.

Since the 1980s, historic preservationists and current developers have shown renewed interest in metal ceilings for both historic structures and new construction. Today, some manufacturers even produce the metal panels with a tin-plate finish, finally enabling the product to deliver on its namesake.

V. Moeslein’s Stamped Steel Ceilings and Sidewalls V. Moeslien, New York, 1894

As the earliest metal ceiling catalog in the BTHL, this resource contains multiple design options as well as instructions on application to wood furring strips. The text also advises owners not to remove existing plaster ceilings but to apply furring strips over them.

Manufacturers of Northrop’s Metal Ceilings & Walls Catalog No. 9 Northrop Coburn & Dodge Co., New York, c. 1900

Northrop’s stamped steel ceilings were designed “with higher artistic effect” for those who “desire the most artistic architectural finish for interior decorations.” The panels were fabricated from 29-gauge, cold-rolled steel and fully primed on all sides before shipping.

Encaustic Metal Ceilings Burned on Enamel, Wheeling Corrugating Co., Wheeling, W.Va., 1906

The Wheeling Corrugating Co. was a major manufacturer of stamped sheet metal for both exterior and interior applications. This 1906 catalog features color plates with its patented burned enamel finish, which it called “encaustic metal.”

Metal Interior Decorations, Eller Manufacturing Co., Canton, Ohio, c. 1900.

Eller’s stamped steel ceilings were designed with “patterns that would please the eye and harmonize the classical arts and make lasting beauty.” Templates include Greek, Romanesque, Gothic, Renaissance, Rococo, oriental, empire, colonial, Louis XIV, and stucco.

The Penn Metal Ceiling and Roofing Co., Philadelphia, 1905

The Penn Metal Ceiling and Roofing Co. offered a variety of ceiling and sidewall panels designs, including “deep mould” plates that provided a higher relief. Costs range from $7.75 per 100 square feet to $13 per 100 square feet for the deep molding.

Sheet Metal Building Material for Interior and Exterior Use, W.F. Norman Co., Nevada, Mo., c. 1910

This catalog contains various metal products for construction including roofing and siding materials as well as some decorative metal ceiling offerings, inviting readers to “write for the complete ceiling catalog.” The Norman Co. still exists today and continues to market its original line of stamped metal ceilings from the early 20th century.

Wheeling Metal Ceilings Catalog No. 317, Wheeling Corrugating Co., Wheeling, W.Va., 1925

This is the most extensive metal ceiling catalog in the BTHL collection with nearly 100 ceiling designs and wall panels. This publication also includes numerous completed examples in retail and commercial spaces.

Metal Ceilings and Walls, Milwaukee Corrugating Co., Milwaukee, 1936

This 1930s catalog features a patented metal ceiling and wall system replicating heavily textured plaster walls that “[suggest] the Spanish motif.”

Berloy Steel Ceilings and Walls, Berger Manufacturing Division, Republic Steel Corp., Canton, Ohio, 1941

This is the most recent metal ceiling catalog in the BTHL, featuring Art Deco style plates with an optional aluminum coating that provided a shiny metal appearance or rust- and stain-resistance when painted.