Beam. The top-of-line Serenity IQS series comes with a 10-year w…

Central vacuum systems require little maintenance. Unlike conventional vacuums that leak if bags tear or become overfull, the systems have large capacity dust collectors that won’t tear or leak, so they generally won’t release particles into the air even when neglected. But to assure that absolutely no household dust is ever recycled into indoor air, the American Lung Association recommends cleaning with a central vac that vents particles to the outside of the house. Most central vac manufacturers provide this option, and many have high-quality, self-cleaning HEPA filters, such as Beam’s Gore-Tex filter system that screens particles down to 0.3 microns at 98% efficiency.

Central vacuum systems also have larger, more powerful motors than you could lug around on an upright, thereby doing a better job of deep cleaning, especially on carpets. “Central vacuums provide up to five times the suction power of a portable with 100% of the vacuumed dirt removed to a dirt canister,” says Amy Wesely, floorcare marketing manager at H-P Products.

A Three-Part System

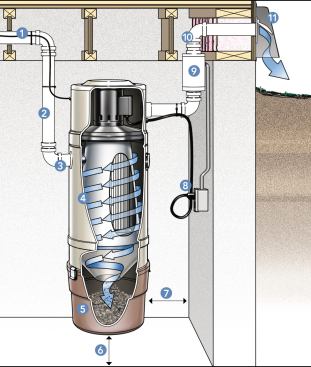

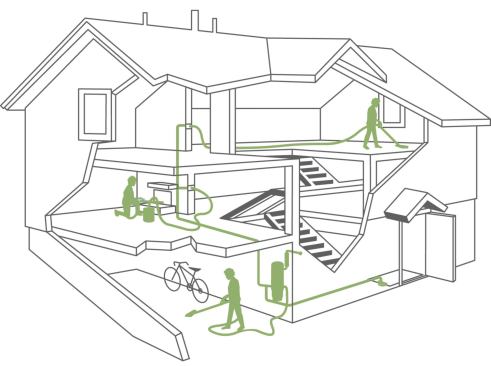

A central vacuum system contains three major components: a power unit that holds the motor, a filtration system with a receptacle to collect the dirt, and a network of PVC pipes plumbed through the walls and floors, terminating at inlet valves where users plug in the hose for a host of cleaning tools and attachments.

In the old days, a central vacuum sweeper resembled a powerful shop vac, serving up strong suction to absorb dirt but lacking the belt-driven agitator brushes common on conventional uprights. Since the 1990s, central vacuum tools have improved. They now include powerful electric or air-driven turbine brushes, plus a wide array of convenience accessories from crevice tools and upholstery cleaners to concrete patio scrubbers and pet grooming kits.

The heart of the central vac comes at the power unit, the canister-like element that hangs on the wall and holds the motor and filtration system. Within the canister, a powerful electric motor spins a turbine, creating suction. The power of vacuum systems is measured by “water lift” and air flow. Water lift represents the sucking force the vacuum exerts when applied to a laboratory water column, gauged by how many inches the water in the test column rises. Air flow is measured in CFM, or cubic feet per minute, of air flow without resistance.

A mathematical formula called air watts combines water lift and air flow to rate the overall power (watts) generated by the vacuum. Air watts is recognized by the American Society of Testing and Materials (ASTM) as the best way to measure the actual cleaning force of a vacuum system. You won’t find the Energy Star label on any system. “As an industry, it hasn’t happened because it’s an appliance that runs intermittently without great impact on energy consumption,” says Brian Campbell, product development manager at Electrolux.

Choosing the System

The first step to selecting a central vacuum system is matching the system’s air watt rating to the size of your house. Most manufacturers offer a motor-to-house-size compatibility table to make the calculation easy. When evaluating product quality, select a system with sealed bearings (to keep the dirt out), bypass cooling (a separate stream of air that cools the motor apart from the air that draws in dirt from the home), and the longest warranty available—the longer the warranty, the more confident the manufacturer is about the product.

To qualify for LEED certification points, the filtration system should include a HEPA filter and the option to pipe the exhaust outside. While some manufacturers say the exhaust air in their system is so clean this final precaution is unnecessary, all of the leading air quality certification criteria, including LEED and NGBS, require outside venting.