Timothy Hursley

TOOLBOX

Hotboxes

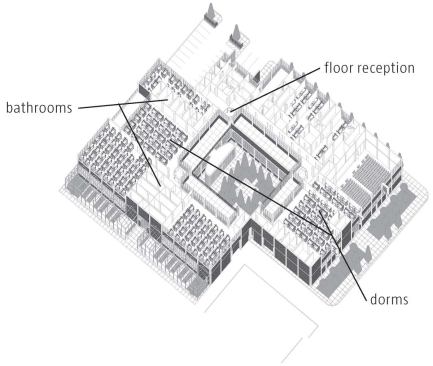

To ensure that the building remains sanitary, the architects designed hotboxes-separate metallined rooms-off one of the men’s and one of the women and children’s dorms. These rooms sport specialized heaters (connected to and powered through the central heating system) that heat the space to a scorching 180 degrees. The process kills any vermin, be it lice or bacteria, that might be clinging to the clothing, keeping them safe from infestation and disease. When visitors arrive for an overnight stay, they are asked to remove their clothing, take a shower, and change into a mission-issued nightshirt. Their clothes are immediately put into the hotbox and sterilized. The same happens to the bedding after use and to any donated clothing.

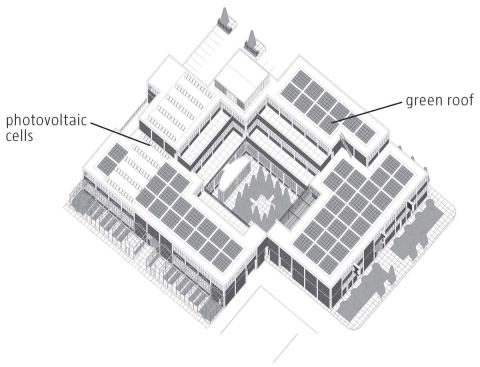

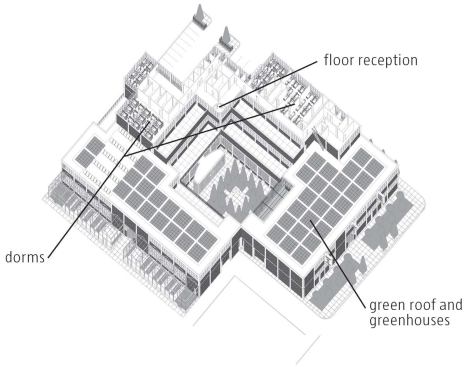

Greenhouses and Composting

“It all began with worms,” says Tigerman. The greenhouses on the roof of the mission are run by Nance Klehm, a third-generation nursery owner and expert in organic composting and farming. She brought 10,000 worms to start the greenhouse’s composting program, and through the addition of table scraps and other waste from the nearly 6,000 daily meals served since the mission’s opening in October, the number of worms has swelled to 30,000 in just a few months, with an eventual goal of 3,000,000. The worms create organic compost, which sells for a pretty penny in the Chicago market and ensures the rapid and robust growth of organic lettuce and tomatoes.

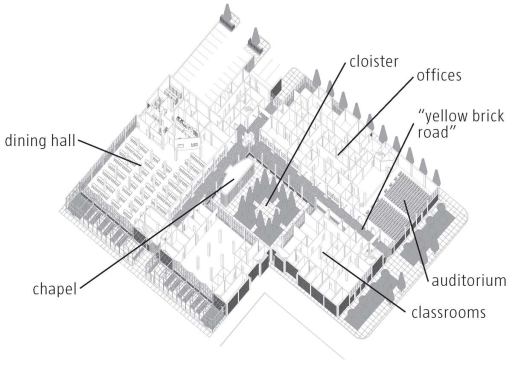

The spoils of these gardens will be sold this summer at a farmer’s market in the cloister, with the income from both that and compost sales going directly back to fund the mission’s programming. Bunks

The mission’s 1,000 beds were custom designed by Tigerman and manufactured by the American Bedding Company out of Tennessee, a company that specializes in institutional contracts. The design of the metal bunks was influenced by Tigerman’s time in the Navy, when he learned about cramming a large number of people into a small space. Designed to be narrow (30 inches wide, as opposed to a standard 36 or 39 inches wide) to allow for broader aisles and more rows, the beds are made to be indestructible. Made from powder-coated steel tubing, the beds have a solid baked-enamel panel at pillow-level to offer a measure of privacy for residents. The rest of the panels are perforated to allow for a regular flow of fresh air. Speced to be 6-feet-3-inches-long to accommodate varied heights, the beds can be configured as a single bed, a bunk bed, or a set of two bunk beds connected to one another.