SOM/Cesar Rubio

PROJECT Cathedral of Christ the Light

CLIENT Roman Catholic Diocese of Oakland

DESIGN ARCHITECT Skidmore, Owings & Merrill, San Francisco—Craig Hartman (design partner); Gene Schnair (managing partner); Patrick Daly (senior design architect); Keith Boswell (technical director); Ray Kuca (project manager); Eric Keune, David Diamond, Henry Vlanin, Denise Hall Montgomery, Jane Lee, Chris Kimball, Christiana Kyrillou, Surjanto, Gary Rohrbacher, Elizabeth Valadez, Mariah Nielson, Peter Jackson, Lisa Finster, Ayumi Sugiyama, Doug Smith, Liang Wu, Katie Motchen (architecture project team); Tamara Dinsmore, Chanda Capelli, Carmen Carrasco, Suzanne Le Blanc (interiors project team); Lonny Israel, Alan Sinclair (environmental and liturgical graphics)

EXECUTIVE ARCHITECT Kendall/Heaton Associates, Houston

STRUCTURAL ENGINEER Skidmore, Owings & Merrill, San Francisco—Mark Sarkisian, (director, structural engineering); Peter Lee (senior structural engineer); Eric Long (project structural engineer); Sarah Diegnan, Lindsay Hu, Jean-Pierre Chakar, Rupa Garai, Aaron Mazieka, Shea Bond, Ernest Vayl, Feliciano Racines (project team)

GENERAL CONTRACTOR Webcor Builders

CONSTRUCTION AND PROGRAM MANAGEMENT Conversion Management Associates

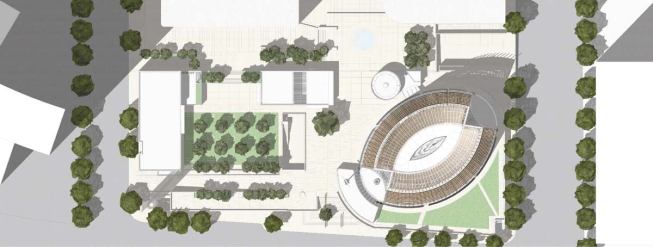

LANDSCAPE ARCHITECT Peter Walker and Partners

ELECTRICAL ENGINEERING The Engineering Enterprise

MECHANICAL ENGINEERING Taylor Engineering

COST $190 million

SIZE 224,000 square feet

TOOLBOX

Software

The design team used a variety of programs to create the drawings and renderings for the project. Construction documents were created in AutoCAD ADT 3.3, otherwise known as version 2002, but for certain elements, such as the dynamic Alpha and Omega walls, the team turned to 3-D modeling program Form Z, version 4.0, to help determine angles and potential stresses. Structural models for the entire structure were created in SAP 2000. 3D StudioMax was used to create 3-D renderings of the building at all times of day, and Adobe’s Illustrator and Photoshop, version CS, were used to create color site plans and elevations.

Seismic Base Isolators

To protect the building from future earthquakes on the surrounding web of fault lines, the building’s cast concrete base rests on 34 seismic base isolators to help the building ride out any shocks. The individual base isolators are arranged in a matrix, with the load evenly distributed. SOM’s in-house structural engineering team, led by director Mark Sarkisian, specified friction-pendulum base isolators, each one with a 4-foot-diameter steel bearing. This particular variety of base isolator employs a sliding system, with an interfacial material that slides across stainless steel.

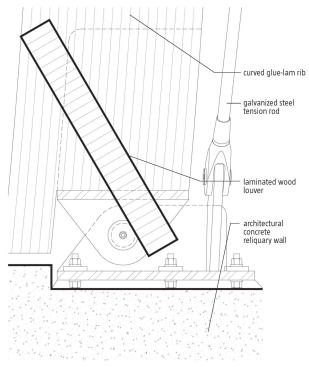

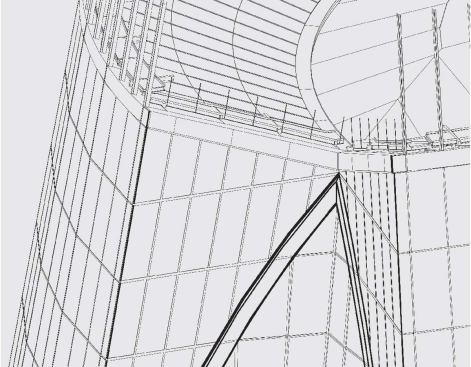

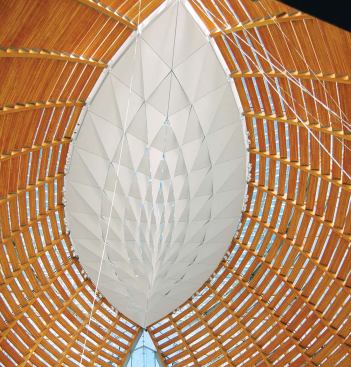

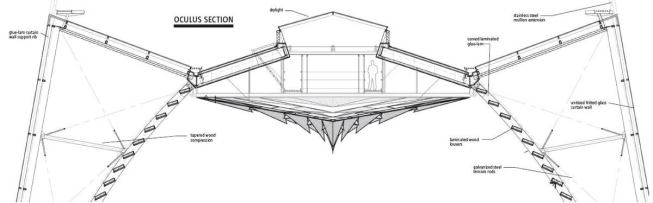

Glue-lam Ribs

The actual geometry of the interior space was based on more than just the desire for a certain volume; it was based also on necessity. The width and curve of the wood structure’s vertical glue-lam beams was informed in part by the 110- foot-long-by-13-foot-wide bed of the flatbed trucks that could make it over the bridges and through the tunnels on the path between the wood’s origin in Portland, Ore., and the Oakland building site. The width was based on the standard 1-1/2-inch-by-11-1/4-inch dimensions of the stock laminations used in glue-lam construction.

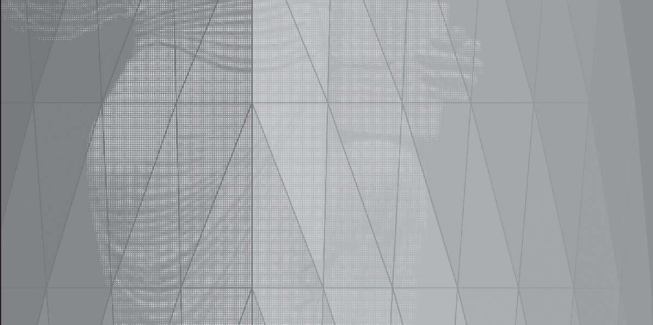

Omega Wall

When the bishop voiced his desire to include a strong representational image of Christ in the building, Hartman wanted to make it integral to the architecture. As a guide, the church supplied a digital image of a carved stone relief at Chartres Cathedral. A team of architects, environmental graphic designers, and members of SOM’s digital design group worked together to create an algorithm that sorted the pixels according to brightness. The image was tweaked to enhance its legibility before then being mapped onto the 3-D surface. In finished form, the backlit image will rise more than 50 feet high, composed of more than 90,000 holes, ranging in size from 4mm to 24mm, laser cut into the anodized aluminum panels.