“I appreciated how they considered varying the thermal properties of this solution, given that the thermal performance of ETFE has been the main challenge with the material.” — juror Mimi Hoang, AIA

Pity the architect asked to deliver a building for the Illinois Institute of Technology. The 120-acre campus south of downtown Chicago was largely designed by Ludwig Mies van der Rohe in the decades after World War II, and added to in subsequent decades by the likes of Helmut Jahn, FAIA, and Rem Koolhaas, Hon. FAIA, So when the school asked one of its professors of architecture, John Ronan, FAIA, founding principal of John Ronan Architects, for a new center for entrepreneurship, he knew he had to deliver something special—both architecturally striking and technologically innovative.

John Ronan Architects

Many of the campus’s Mies-era buildings are sheathed in glass, a distinctive feature that lends a skin-and-bones lightness to the master architect’s industrial aesthetic. “My question was,” Ronan says, “if the steel-and-glass buildings were lightweight for their time, what would be the equivalent for our time?”

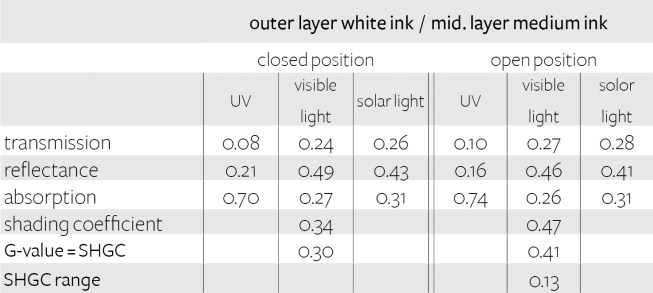

Ronan decided the solution was to update that look using a material with the performance of glass at a fraction of the weight—ethylene tetrafluoroethylene (ETFE), a translucent, resilient plastic film used to cover wide spans like arena roofs. By placing four layers of ETFE alongside each other in a window, in place of glass, and then adjusting the width between them, Ronan realized he could modulate the material’s insulative capacity—think of a pillow of air that inflates and deflates depending on the weather. “You can tune the building to the climate,” Ronan says. “With the right sensors and controls, it can respond to the weather in real time.”

These ETFE “windows,” which run along the second floor, have three air chambers inside; each assembly is separated by steel mullions. When the building needs to retain heat, the chambers can be expanded using pneumatic controls, creating air pillows that give the building a soft, supple look.

courtesy John Ronan Architects

ETFE weighs about 1 percent of what glass does, which reduces the load on the building’s structure while still delivering the same level of insulation as tripled-paned glass. But the differences don’t stop there: “One of the qualities of ETFE is that it’s acoustically transparent,” Ronan says, meaning that the chatter of birds and the murmurs of passersby will filter in through the windows, blurring the line between interior and exterior. “That way, students inside will have the sense of being outside.”

Ronan’s building, the Ed Kaplan Family Institute for Innovation and Tech Entrepreneurship, sits at the center of the Mies campus and will be finished by July 2018. While the building’s true performance remains to be seen, Ronan sees solutions like his as part of a new wave of architectural components that put less pressure on active HVAC and lighting systems, and more on the manipulation of passive effects. “I think it’s the future of buildings, not just static structures but responsive ones,” Ronan says. “We’re going to see architecture soon that does more, so the systems do less.”

John Ronan Architects

Project Credits

Project: Dynamic ETFE Façade for the Ed Kaplan Family Institute for Innovation and Tech Entrepreneurship

Client: Illinois Institute of Technology

Design Firm: John Ronan Architects, Chicago . John Ronan, FAIA (principal); Marcin Szef, Sam Park, Eric Cheng, Danielle Beaulieu, AIA, Laura Gomez Hernandez (project team)

Fabricator: Vector Foiltec

Structural Engineer: Werner Sobek Group, Stuttgart

M/E/P Engineer: dbHMS

General Contractor: Power Construction

Funding: Illinois Institute of Technology

Special Thanks: Ludwig Mies van der Rohe