Jukka Seppala/Helinski University of Technology

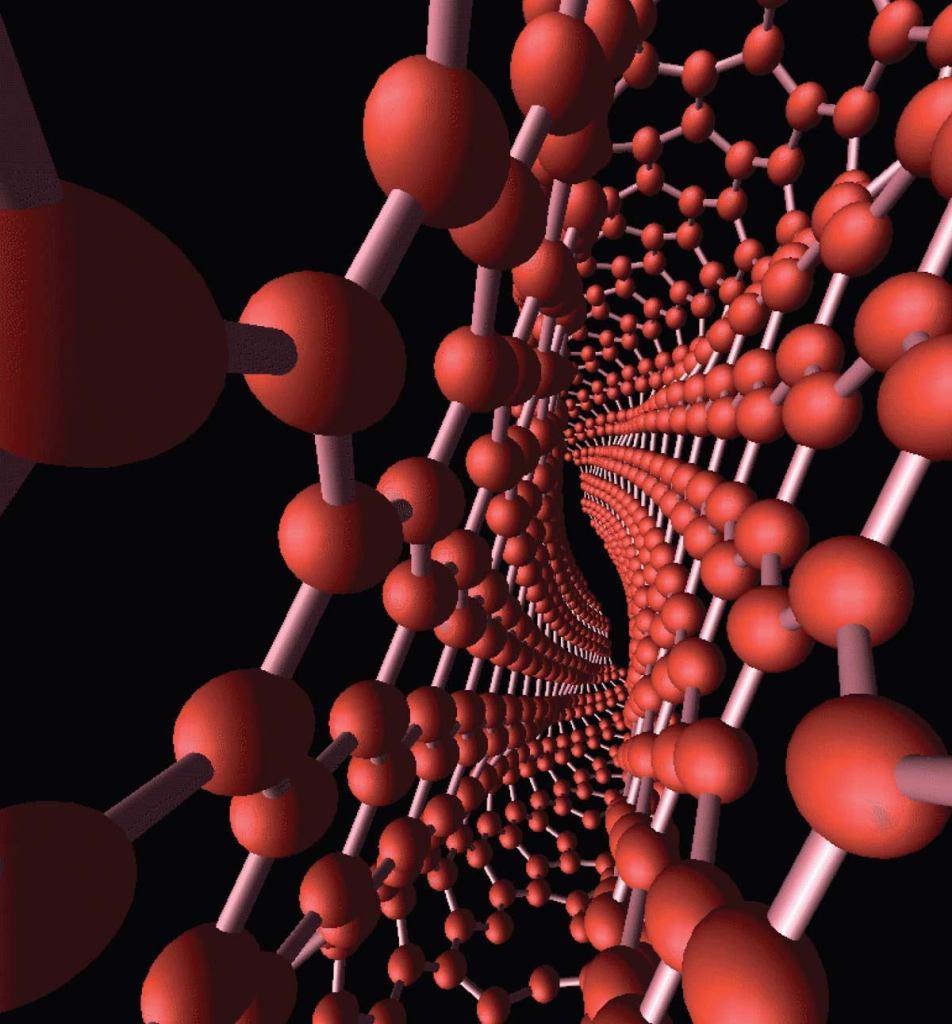

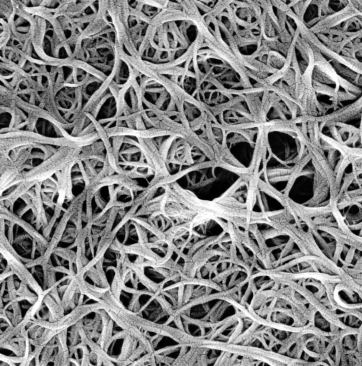

Biomaterial structural composites, like these panels made from f…

Nanocoatings Nanomaterials stand to revolutionize insulating methods because they are structured at the molecular level to trap air between particles. They are far more efficient than traditional insulators like fiberglass and polystyrene (which work at the macro level), without the environmental harm associated with those materials. And because it traps air at the molecular level, an insulating nanocoating even a few thousandths of an inch thick can have a dramatic effect.

Nanogel insulation, made by the Cabot Corp., is a form of aerogel, the lightest-weight solid in the world. Known as “frozen smoke,” nanogel is 5 percent solid and 95 percent

air. The high air content means that a translucent panel 3.5 inches thick can offer a high insulating value (up to R-28). Another company, Nanoseal, makes insulating paints for buildings. Its insulating coating—applied in a layer only seven-thousandths of an inch thick—is being used on beer tanks in Mexico by Corona, resulting in a temperature differential of 36 degrees Fahrenheit.

Nanocoatings are used to insulate both new and existing materials, or to protect wood, metal, and masonry, without the hazardous off-gassing of many other coatings. Nanoengineered ultraviolet curable protective coatings by Ecology Coatings won last year’s Silver Award for Innovation in The Wall Street Journal‘s Technology Innovation Awards competition. “Garbage, paper, and other renewables can be formed into products,” says Sally Ramsey, chief chemist at Ecology Coatings, “but they have a tendency to dissolve in water. We can use a very light coating of our product to waterproof these, and they can be used as a substitute for plastic.”

Good for the environment, this technology may be good for our health, too: The Hong Kong subway system has coated its cars’ interiors with titanium and silver dioxide coatings that kill most of the airborne bacteria and viruses they come into contact with. And in cleansers and interior paints already used around the world (Behr Premium Plus Kitchen & Bath Paint is one example), nanoparticles fight mildew.

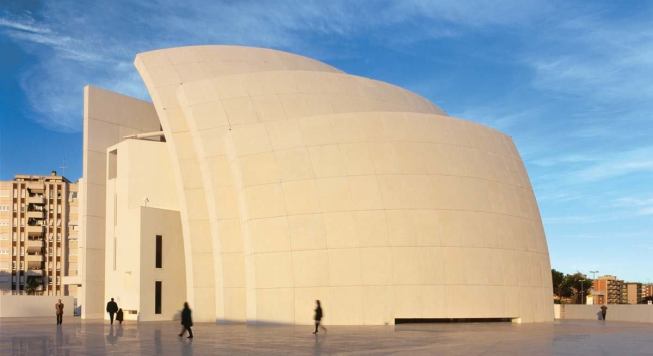

Nanocoatings can break down dirt as well. PPG Industries and Pilkington Glass both offer self-cleaning window glass that harnesses nanotechnology. The Jubilee Church in Rome, designed by Richard Meier & Partners Architects, features self-cleaning concrete: Photocatalytic titanium dioxide nanoparticles in the precast panels (manufactured by Italcementi) make them shed dirt. The panels trap airborne pollutants in a nanoparticle matrix on their surface, then decompose them.

Similar depolluting nanocoatings can be applied to almost any surface, making it a smog-eating machine. In the near future, road surfaces, bridges, and tunnels may be able to counteract pollution. The Swedish construction giant Skanska is now involved in a $1.7 million Swedish-Finnish project to develop catalytic cement and concrete products coated with depolluting titanium dioxide.

Smart environments In the future, the environment will interact with occupants in ways hardly imaginable today, creating what a 2005 United Nations report calls “an internet of things.” Tiny nanosensors embedded in building materials will soon be able to track movement and detect temperature changes, humidity, toxins, weapons—even money. Sensors will pick up on users’ preferences and attributes, which will then trigger responses in the intelligent objects around them, dimming the lights, altering the temperature, or—as is already happening with “push” technology that marketers use to blitz cell phones—alerting them to nearby sales and events.

Soon, the design and construction of buildings will incorporate a rich network of interacting, intelligent objects, from light-sensitive, photochromic windows to user-aware appliances. Buildings will not be static but will change constantly as their components continuously interact with users and each other. These dynamic environments will be almost organic in their ability to respond to changes, so architects will need to learn to design for change.

No longer will we call the work of design done when construction is complete. That will be only the beginning of the design process, thanks to nanotechnology.

George Elvin is the director of the Green Technology Forum (greentech forum.net), a research and advising firm focusing on nanotechnology and biotechnology for growing green businesses; he is also an associate professor in the school of architecture at Ball State University. He can be reached at elvin@greentechforum.net.