Raw Materials: Nylon Carpet

Shaw Contract Group uses new and recycled materials to produce carpet at its mills in Georgia, following these basic steps.

Jameson Simpson

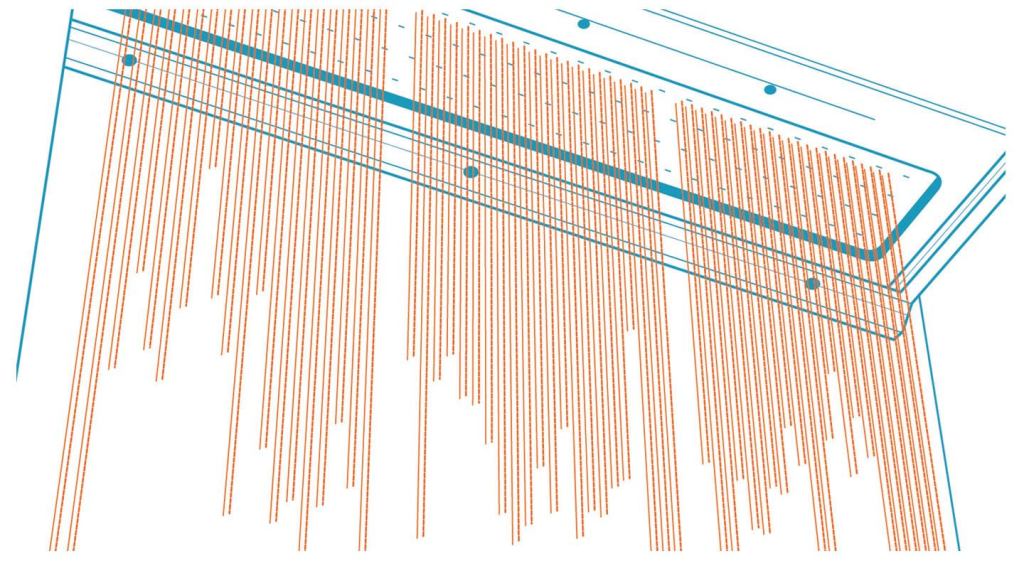

Extrusion: The nylon for Shaw's carpets arrives by rail or tractor-trailer in the form of resin pellets or chips, some brand-new and some recycled. From storage silos, the pellets are fed into an extruder, which melts them together at 400 to 425 degrees Fahrenheit. The softened material is like taffy. It then enters a controlled feed into a "spin pack" (shown), the exit end of which is perforated like a showerhead. The extruded nylon cools as it falls down about three stories, like a shower of fishing line. It eventually winds up rolled onto cones.