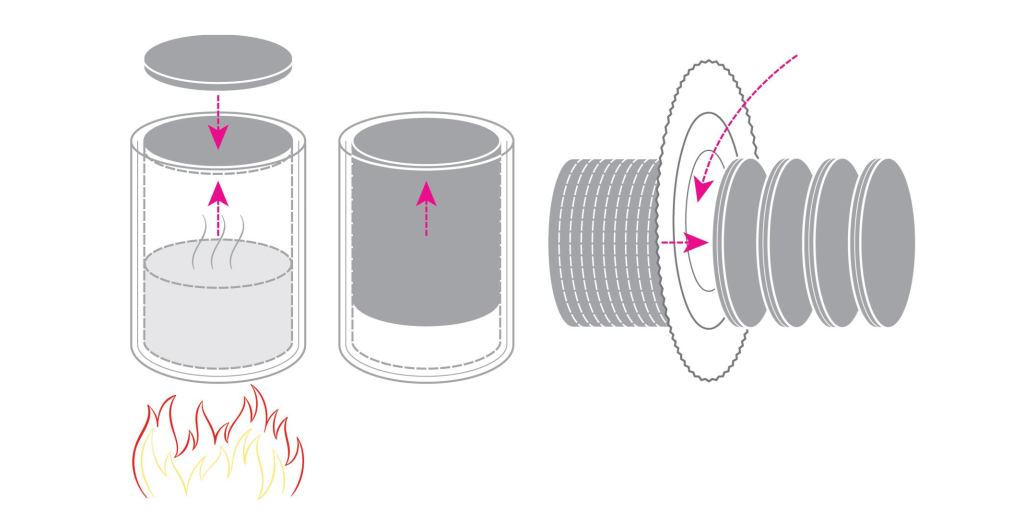

Mounting and SlicingTo start the process, a tiny piece of silicon carbide (SiC), called a seed, is mounted in a crucible that is also filled with SiC. Heat is applied in a furnace and the SiC turns into a vapor that deposits on the seed to form a large crystal called an ingot. The ingot is sliced with a saw into thin wafers that become the foundational substrate upon which the LED will be built. Each ingot is now 4 inches in diameter, but the company is in the process of making the transition to 6-inch-diameter ingots, which will increase the number of LEDs on a single wafer and help make LED lighting more cost-effective.

PolishingEach wafer is buffed into a smooth finish and the surface is washed and dried in preparation for LED fabrication. Washing can also happen after elements are baked onto (see step three) depending on the type of LEDs being produced.

Depositing and DicingIndium, gallium, and nitrogen are baked onto the wafer to form the active layer of the future LED. The wafer is transferred to another machine where it is diced into as many as 100,000 tiny LED chips. When voltage is applied to a chip, electrons and holes form and recombine in the active layer to produce light, generally blue or green in color.

BinningEach LED chip on a wafer is lit to check for brightness and color point. They are then sorted into bins. Each bin is a sheet of sticky film onto which the sorted chips are organized into neat rows. The bins then are manually inspected again for quality control. Bin size varies based on bin specifications such as brightness and color point. A bin can contain chips from various ingots as long as they meet specifications for that particular bin.

FinishingThe LED chip then is glued onto a package where phosphor is added. Some of the blue light generated by the LED chip is converted by the phosphor to other colors such as red and yellow. These new colors combine with the remaining blue light to create white light. Electrodes are stitched in before the package is topped with a lens to help direct and shape the light. Cree produces millions of LEDs daily.