When architect Matthew O’Malia started his Maine-based design-build firm in 2008, it didn’t take long for him to run into the construction problem that would lead to an unplanned career expansion into building products entrepreneurship.

O’Malia, who is no stranger to design innovation, built the first certified Passive House in Maine and expanded adoption of these concepts—rooted in small heating and cooling loads—throughout New England and beyond.

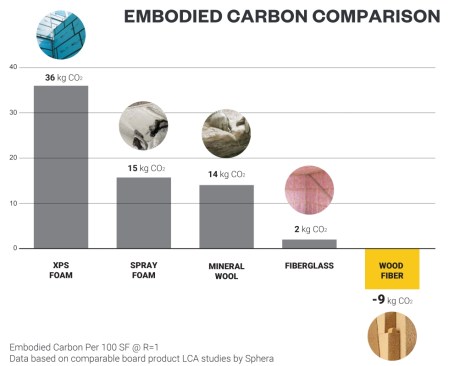

But as the scale and reach of his projects grew, O’Malia knew there was an unsustainable link in his materials supply chain. Fossil-fuel derived insulations, the mainstays of the mainstream market, were itchy, scratchy, and prone to toxic off gassing. O’Malia’s construction crews couldn’t stand using them, and while they reduced operational energy use, their high embodied carbon levels canceled out those savings from a climate change perspective.

Wood fiber insulation is the only scalable, affordable, carbon-storing insulation on the market.

A better solution, it turns out, already existed. Wood fiber insulation, available for more than two decades in Europe, now accounts for nearly $1B in sales annually on the continent. Long coveted by the specifier community, but too costly to import for day-to-day use, wood fiber insulation is finally being manufactured stateside this year by Maine-based TimberHP, the company co-founded by O’Malia and his business partner, the company’s CEO, materials chemist Dr. Joshua Henry.

Priced for mainstream adoption and scalability, the products coming online this year work as easy drop-in replacements for other above-grade insulations or as a stand-alone comprehensive system: TimberBoard, TimberBatt, and TimberFill—together or used alone—achieve unmatched performance.

Wood fiber insulation’s high-performance attributes impress.

A small amount of non-toxic retardant, added to the fill and batt products, delivers a Class A flame spread (ASTM E84 Standard). Board products achieve a Class B spread (ASTM E84 Standard) on their own. Borate additives protect against fungi, including mold and mildew (ASTM C739), and deter termites, carpenter ants, and wood boring beetles. Wind-tight and vapor-open wood fiber insulation offers superior building envelope, thermal, moisture management and industry-leading acoustic performance—with stable long-term R values.

When walls and ceilings are vapor open, not only is the building protected from unwanted moisture build up, but indoor humidity can be buffered, leading to increased comfort and better air quality.

Unlike many other insulation types, TimberHP products do not trap moisture in the built environment.

Wood fiber insulation is biogenic, non-toxic, renewable, and recyclable, making it safe for builders and homeowners alike.

Manufacture of the products, which takes place in Maine, inside a renovated former paper mill, is breathing new life into the state’s forest products industry. Wood waste, once used, almost exclusively, to make pulp for papermaking, now needs other outlets. It’s this material—leftover wood chips from sawmills and small diameter, low value logs—that TimberHP is turning into insulation that arrives at a job site carbon negative and safe to cut, handle, and install. Learn more at timberhp.com.