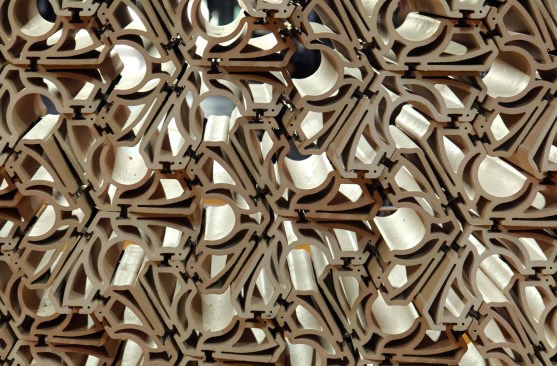

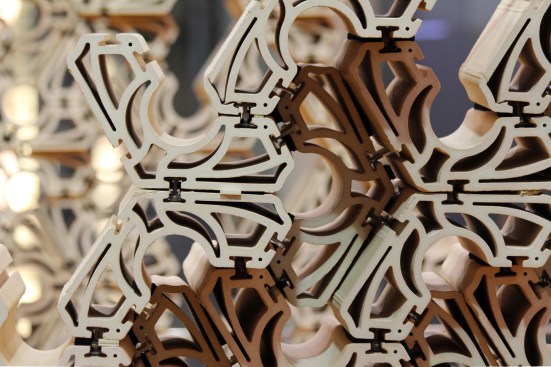

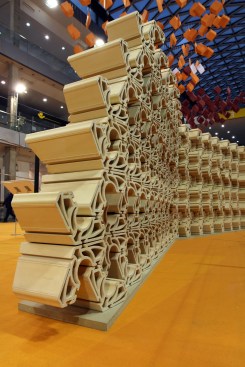

Two tessellated walls on display earlier this month at the annual Cevisama surfaces tradeshow stood out from the rows of mosaic, tile, and solid-surfacing products crowding the exhibition hall in Valencia, Spain. The walls were designed using a novel, low-cost ceramic customization technique developed by students and researchers at the Harvard University Graduate School of Design’s Material Processes and Systems Group, led by director Martin Bechthold and, for this installation, in collaboration with the Spanish Association of Manufacturers of Ceramic Tile. Like the group’s 2015 installation, this year’s “Extruded Tesselation: Ceramic Tectonics” challenges viewers’ preconceptions of the solid material with mind-boggling assemblies of planar, folded, and curved forms.

GSD – MaP+S

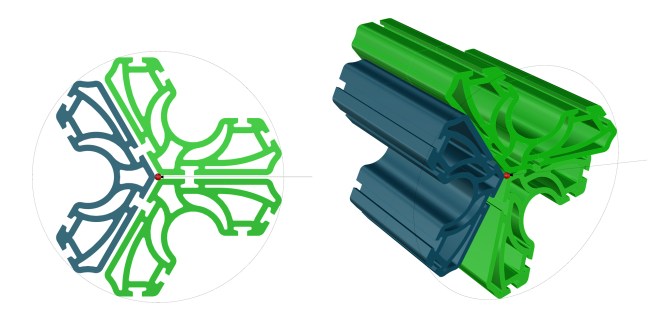

Three modules, two of which (green) have identical cut-off angles, would connect with a clip or cement at the attachment point (red dot).

The ornamental wall wasn’t just for show. Extruded from a single die to minimize tooling costs without sacrificing the need for design variation, the collection of modules came together to create a 3D feature wall that was both structural and permeable to daylight. The modules (example, left) were made of clay and connected with one or more others at a central attachment point. The modules can be cement-bonded for use in permanent installations, such as an interior wall, or dry-stacked and clipped together for temporary applications, as with the Cevisama installation.

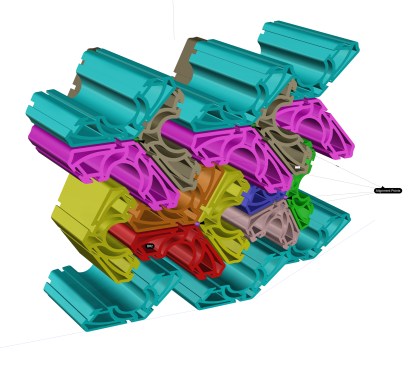

The Cevisama installation, which was up for the show’s Feb. 1 to Feb. 5 duration, comprised 700 elements ranging from 15 centimeters (5.9 inches) to 60 centimeters (23.6 inches) in length, in turn dictating the wall assembly’s width when stacked. Variations in length and cutoff angles resulted in 38 unique elements. The team used robotic manipulators fitted with wire cutters as well as CNC disk cutters to trim the modules’ ends to custom lengths during the extrusion process. Read more about the group’s research here.

GSD – MaP+S

Colors indicate identical cutoff angles, though different lengths exist within each group.

GSD – MaP+S

GSD – MaP+S

GSD – MaP+S

GSD – MaP+S

GSD – MaP+S