Project Description

For Ruth Mandl, AIA, and Bobby Johnston, AIA, of Brooklyn, N.Y.–based Co Adaptive Architecture, the decision to renovate their own house to meet the Passive House standard was easy. The approach is relatively new in this country—the first U.S. project built using the criteria was completed in 2003. But in Europe, the Passive House framework—which calls for an airtight envelope, minimal heating and cooling, and minimal energy usage—dates back to the early 1990s.

Mandl’s parents did a Passive House renovation of a 1960s house in Vienna designed by her architect grandfather. The end result is “really something you have to experience to fully understand,” she says. “It feels different: the comfort, the quality of air, and the quietness.” Mandl and Johnston’s own Brooklyn brownstone dates to 1889, and they wanted to keep as much of its historic character as possible, while bringing it up to the near net-zero energy-efficient standards that Passive House requires.

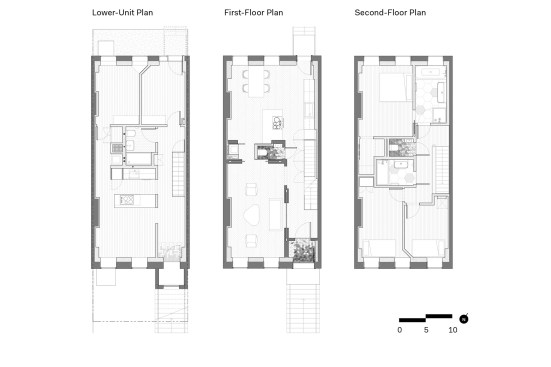

Mandl and Johnston’s first step was to divide the property into two units (a ground-floor apartment and a two-story unit above, where they would live). Then, they focused on the most involved aspect of the renovation: creating an airtight envelope.

The front and back walls had no insulation to speak of, just plaster and lath over 2 inches of furring channels that sat directly on the inner surface of the masonry structural wall. To create a much tighter envelope, the interior walls were stripped to the masonry and built back with the following layers: a 2-inch air gap; 2×6 framing; an interior membrane; 11/2-inch horizontal furring strips; and drywall. After the membrane was put in place, the gaps in the framing were filled completely with blown dense-pack insulation. Windows were replaced with triple-pane tilt-and-turn units.

The new wall system is substantially thicker than the original, and results in much deeper sills. But it has benefits beyond the insulation, Johnston says. The void formed by the framing “is also used as a service cavity, so we had electrical running in that space. Everything’s contained within.”

The walls were only part of the upgrade: The house now sports a rooftop solar array and pairs an energy recovery ventilator (ERV) with an efficient electric HVAC system to minimize heating and cooling loads. The ERV preconditions the air that blows into the bedrooms, and exhausts that air through the kitchen and bathrooms. “Fresh air is constantly circulating and is filtered upon entry,” Mandl says. “You never get a stale room in a Passive House.”

As it stands, the house is operating as net-positive energy—and the overall load includes usage for both units as well as an electric car charging station. “We get money back every year from Con Ed running the meter backwards,” Johnston says. The architects have begun the process for certification with the Passive House Institute in Germany, but that is not yet complete.

Unfortunately, the extensive remodel meant that some of the historic aspects that Mandl and Johnston had hoped to save did not survive the process. While woodwork could be removed and stored during construction, decorative plaster could not, and some fell prey to the vibrations. But even that shortcoming has a silver lining: “We were able to do more acoustic measures to the ceiling,” Johnston says. “We have resilient channels now, so it’s able to move and last a lot longer. Eventually the plaster would’ve started cracking again.”

“There was a lot of anger directed at us for ‘ruining’ this old house,” Mandl says. That “was very much opposite of what we believe we did, which is to restore it for another 100-plus years. I believe that this is the future of our cities: we have to look at our old building stock and figure out a way to bring them into the future with these new systems.”

Project Credits

Project: Macon Street Passive House, Brooklyn, N.Y.

Client: Ruth Mandl and Bobby Johnston

Architect/Interior Designer: Co Adaptive Architecture, Brooklyn, N.Y. . Ruth Mandl, AIA, Bobby Johnston, AIA, Yashil Mudaliar, Assoc. AIA (project team)

MEP Engineer: ABS Engineering

Structural Engineer: Nate Bergen

Lighting: Co Adaptive Architecture

General Contractor: LB General Contracting Corp.

Size: 2,100 square feet

Cost: $720,000 (construction costs)