Project Description

How Adapa made it possible to build geometrically complex reinforced concrete shells without complex formwork or expensive scaffolding systems?

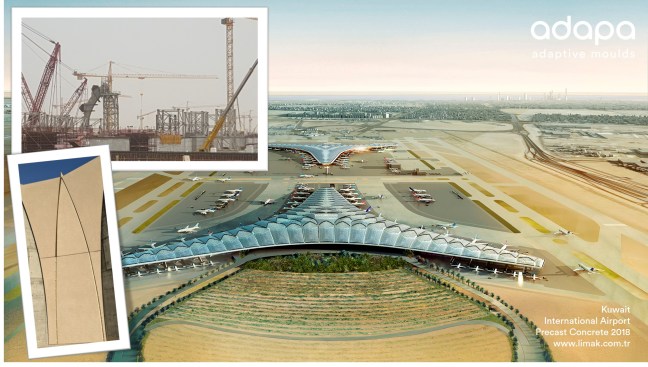

The international airport of Kuwait is currently being extended by a new terminal building designed by Foster + Partner. The new terminal is to be completed by 2022. It has an edge length of almost 1.2 km, a clear height of up to 25 m and a roof area of 320,000 m². The building is characterized not only by its size, but also by the complexity of its roof structure. Despite its large circumference, the roof had to be designed without expansion joints. This had extensive effects on the design and calculation of all components. The roof structure is a statically highly indeterminate system. The interaction between the various components is therefore very complex, so that any change in stiffness of an element has a significant influence on the static load of the other components. The sophisticated design was made feasible with the help of complex digital methods and tools.

Construction site pictures and updates under: https://www.mpw-t2.com/

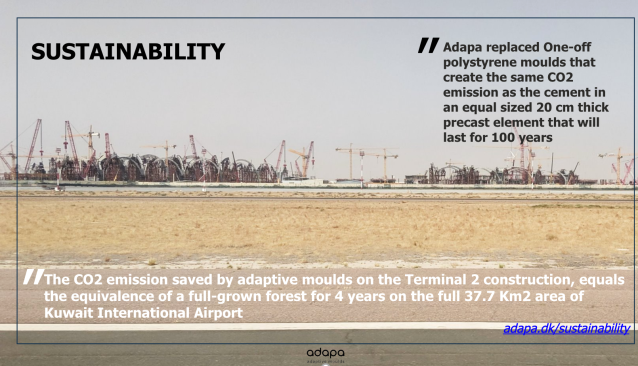

At Kuwait International Airport Terminal 2, the total of curved precast is 300.000 m2, and the average size of precast elements is 8,1 m2. Polystyrene saved is 150,000 m3 or 4,500 Ton – which equals 31,000 Ton CO2. CO2 emission saved equals the equivalence of a full-grown forest for 4 years covering the 37.7 Km2 area of Kuwait International Airport

In addition, the transport of 1,666 truckloads (18-wheeler’s) of polystyrene have been avoided.

Company Limak produced 36.964 reinforced precast shell cassettes on just 85 adaptive moulds with a daily output of up to 160 pcs a day.

13.000 unique panel geometries were designed by Fosters + Partners in the iconic architecture of Kuwait International Airport Terminal 2.

If using traditional CNC milling to create 160 one-off moulds each day, there should have been used a minimum of 300 CNC milling machines. Thus, a facility size difficult to manage and a waste situation impossible to accept.

Besides enabling the construction of the curved architecture, the mould cost each m2 was reduced by the adaptive moulds to a level not far from doing flat precast. .

CO2 emission saved by Adaptive mould equals the equivalence of a full-grown forest for 4 years covering the 37.7 Km2 area of Kuwait International Airport. In addition, the transport of 1,666 truckloads (18-wheeler’s) of polystyrene have been avoided.

The adaptive moulds stood the test in the desert in Kuwait, enduring high temperatures and dusty conditions and yet still supporting the highly auto-mated casting process.

Compared to traditional one-off moulds

5 times less expensive

7 times reduction in facility space

150,000 m3 or 4,500 Ton polystyrene saved

31,000 Ton CO2 emission saved

The co2 emission saved by adaptive moulds on the Terminal 2 construction, equals the equivalence of a full-grown forest for 4 years on the full 37.7 Km2area of Kuwait International Airport