Pleats Please, Issey Miyake, Berlin – Eloueini typically starts …

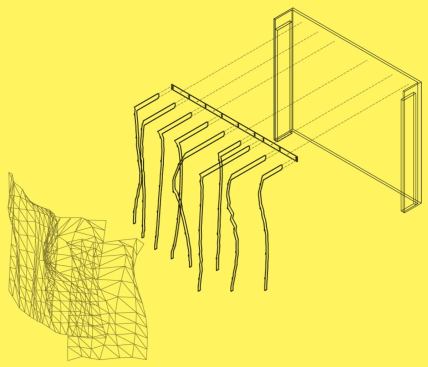

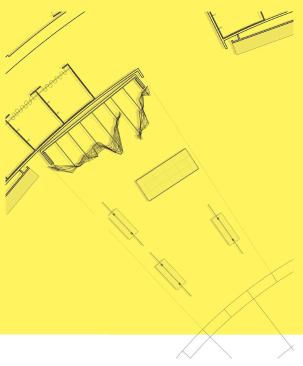

Project: Fashion Show, School Of The Art Institute, Chicago

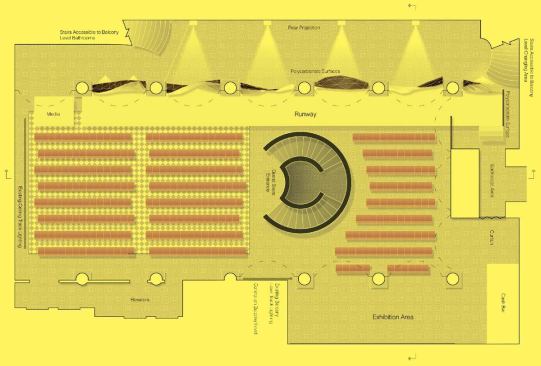

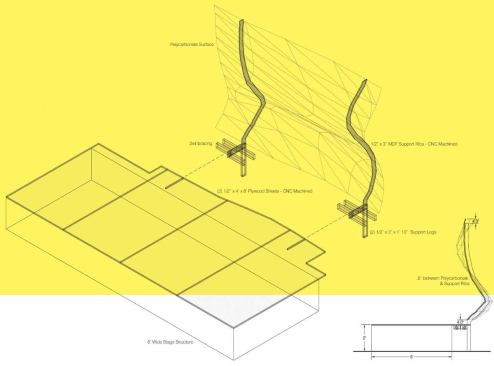

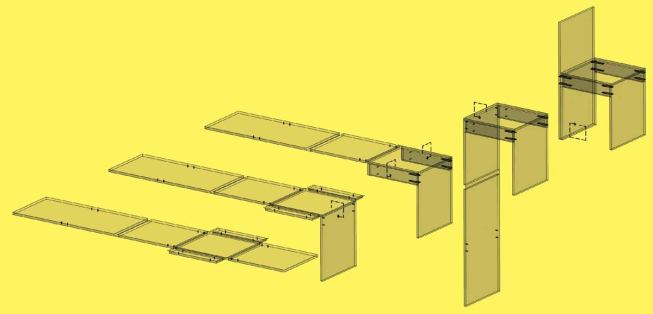

The School of the Art Institute of Chicago commissioned Eloueini to design the stage set for its fashion department’s 71st annual fashion show in May 2005. To maximize seating capacity in the school’s elegant ballroom, Eloueini placed the runway off to one side, along a colonnade. The runway was backlit by luminescent polycarbonate surfaces placed between the columns. At each end, the panels incorporated a flat-screen TV.

Project: Nubik, Grand Arts Gallery, Kansas City

Nubik, a site-specific piece installed in March 2005, created the context for a series of changing exhibitions featuring more than two dozen artists, architects, musicians, and thinkers. Made from a series of nine folded strands suspended from the gallery ceiling by cables, the composition was formed by discrete pods of varying size. By day, the strands diffused direct sunlight passing through skylights overhead. At night, the illuminated form gave the space an otherworldly quality.

Project: Mu Chair

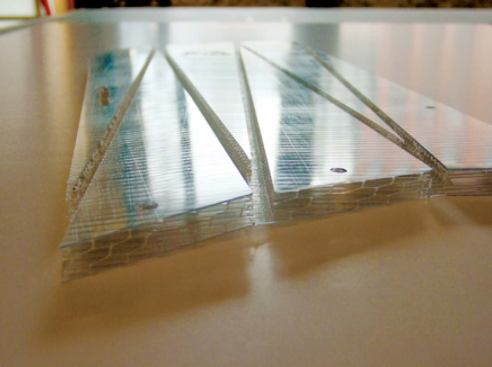

The lightweight and inherent structural characteristics of polycarbonate make it an interesting material for furniture design, says Eloueini. The MU chair is made from a single 2-foot-by-8-foot panel of 100-percent recycled polycarbonate.

Toolbox

Eloueini’s grounding in architecture at Columbia’s paperless studio has led to projects that are designed—and fabricated—using digital technology. The complex, many-faceted surfaces he creates emerge from a sequence of proprietary software, modeling, and fabrication techniques. To get the job done, these implements are found in his toolbox.

Softimage / www.softimage.com

One of the first investments Eloueini made after launching his practice was to purchase Softimage, a program that incorporates animation. Eloueini compliments how the program “applies force to geometry.” He calls it the ideal software to initiate design. The software’s 3-D component is powerful, and 3-D modeling is easy to execute in comparison to other animation programs, he adds. “And Softimage has one of the best rendering engines available.”

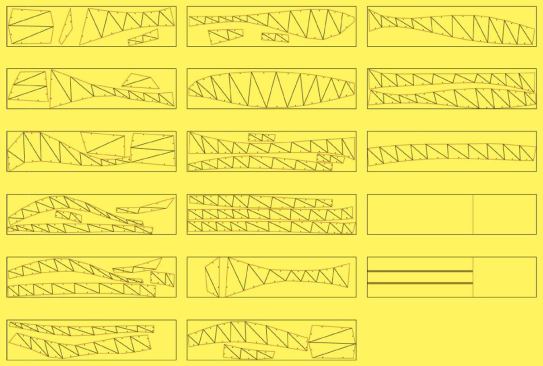

Pepakura / www.tamasoft.co.jp/pepakura-en

Eloueini swears by this inexpensive product as the best software for unfolding surfaces. In the case of the polycarbonate projects, the 3-D geometries are flattened by this program so they can be fabricated with the CNC router.

AutoCAD / www.autocad.com

After the geometric forms are flattened in Pepakura, the drawings are imported into AutoCAD for production of the CNC-compatible files. “It’s kind of an industry standard,” says Eloueini.

Chicago Scenic Studios / www.chicagoscenic.com

When Eloueini began his polycarbonate odyssey for choreographer John Jasperse, Chicago Scenic Studios was his source for a CNC routing machine—one of the few available in Chicago at the time. Using the same router, the company also produced the plywood rib structure for the School of the Art Institute of Chicago’s fashion show stage set.

Industrial Models / www.indmod.com

This precision machine shop in Wauconda, Ill., has CNC milling and water-jet cutting machines. Starting with half-inch-thick aluminum plate, the machines produced the rib structure, racks, and table frame for the Miyake project in Berlin. The same shop also provided the drilling and tapping of the pieces for later screw assembly.

CPI Daylighting / www.cpidaylighting.com

For the high-end Pleats Please showroom, Eloueini purchased stock 12mm polycarbonate glazing panels from CPI Daylighting in Lake Forest, Ill. He tested several available thicknesses before determining that the 12mm product provided the best balance of minimalism and strength. CPI polycarbonate comes only in 2-foot widths.

Green-Tek / www.green-tek.com

Polycarbonate from Green-Tek is about one-fifth the cost of CPI’s product, and it is far less substantial. Eloueini specified its use for the backdrop at the School of the Art Institute of Chicago fashion show, which remained in place for only a few days and was not installed where the public had access to it. The product comes in 4-foot widths.

Zip-ties / www.homedepot.com

For all the state-of-the-art technologies that converge to makes Eloueini’s dreams a reality, the fundamental tool of the final assembly is the humble zip-tie. His source: Home Depot, where a bag of 7-inch zip-ties sells for about $17 per thousand.