U.S. General Services Administration and Westlake Reed Leskosky

A historical view of the lobby of the Wayne N. Aspinall Federal …

The greenest building, preservationists like to say, is the one that is already built. Even greener, however, is the existing building that is sensitively renovated so that it consumes no more energy than it produces. In Colorado, a 1918 federal building is poised to do just that, as it’s designed to be the first building on the National Register of Historic Places to achieve net-zero energy use.

Located in Grand Junction, Colo., the Wayne N. Aspinall Federal Building and U.S. Courthouse is a four-level, 41,562-square-foot Neoclassical structure that has been in continuous use since its construction. Using federal stimulus funds, the U.S. General Services Administration’s (GSA) Rocky Mountain Region sought a sustainable renovation of the building, and required that the work be completed while it remained occupied with several federal agencies. Even with a 1930s addition, the building had become cramped and outdated, with plumbing and other mechanical systems that needed an overhaul. Yet its historic status meant that character-defining features, such as the original arched windows, had to be carefully considered.

After a bidding process, the GSA awarded the contract to the Beck Group, a full-service design/build firm, which hired Westlake Reed Leskosky (WRL) to provide architectural design services and LEED consulting, among other services. In its bid, the team identified the capability of achieving net-zero energy, primarily through the addition of a canopy structure on the roof to house a large photovoltaic array.

“The federal government has a goal to be carbon neutral by 2030,” says Roger Chang, Assoc. AIA, director of sustainability for WRL. “One of our major selling points was that we could show that we figured out how to make an existing building net zero, 17 years ahead of schedule.” (Construction is expected to be complete by January 2013.)

Because the building is listed on the National Register, the project underwent a federally mandated review of its effects on historic features, as required under Section 106 of the National Historic Preservation Act. The design/build team says that the process went smoothly because of all the preliminary research into the building’s history that they had done. They designated a series of preservation zones that helped to determine which elements should be retained and which could be modified.

“We assign zones numbered one through five,” says Paul Westlake Jr., FAIA, managing principal, principal-in-charge, and lead architectural designer for WRL. “Zone one includes the most significant historic features—the exterior, lobby, and corridors—[which] were preserved and restored. Zone five, by contrast, includes areas of the building that have the least important historic fabric, such as a non-public area in the basement for utilitarian use that’s similar to a mechanical or electrical room. Areas within zone five, therefore, are most adaptable to change.” Westlake adds that the project includes the restoration of historic fabric, such as high plaster ceilings and ornamental details, in areas that had been covered by suspended ceilings or other more recent features.

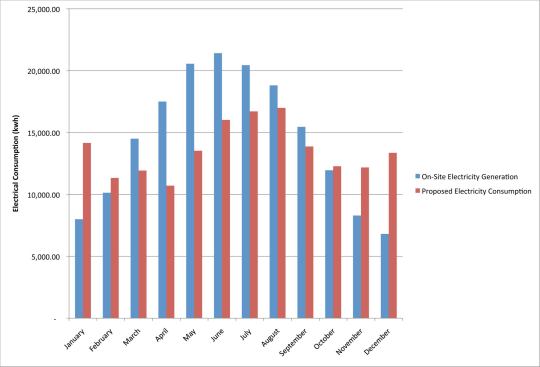

Despite these considerations, preservationists were concerned about the extent to which the original canopy for the PV array—which would have produced 170 kilowatts of power—was visible from the main entrance. “If we had to scale back the canopy, we would have had less PV to generate power for the building,” says Jason Sielcken, GSA’s Rocky Mountain regional project manager. “So we had to offset that by driving down the building’s energy use.”

The design/build team came up with a smaller, 123-kilowatt array that minimized the appearance of the canopy and passed muster with the state historic preservation office. The team also determined that along perimeter walls, a layer of closed-cell, spray-foam insulation with pre- and post-consumer recycled content and drywall could be added without changing or compromising the historic moldings or window openings. Interior storm windows with solar-control film provide further insulation, and were carefully chosen so that they did not visually affect the building’s exterior appearance. The existing windows are numerous enough that more than 90 percent of the interior receives natural daylight.

In addition, a 32-well geothermal exchange system is being installed for heating and cooling. “The geothermal system really helped to push us to the net-zero point,” says Mark Hutton, Beck Group’s integrated project leader. “Construction-wise, it’s definitely been a challenge—the property itself is really small.” In addition to placing wells beneath existing GSA parking on the north and east sides of the property, the team worked out a long-term agreement with Grand Junction officials to place several wells under city alleyways on those sides of the building as well. The system requires the installation of new vertical piping for the wells and horizontal piping that connects all the wells and ties them back to the building. Chang adds that the site’s climate is sunny and arid, therefore allowing for a high level of on-site energy production and use of evaporative cooling to reduce peak cooling demand.

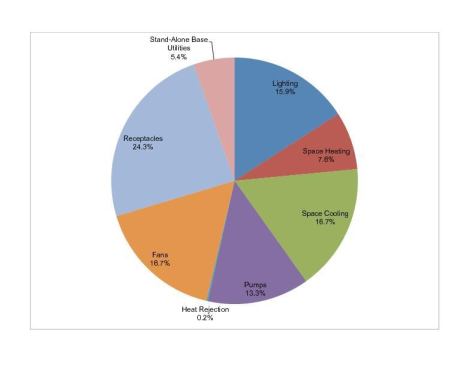

To achieve the net-zero-energy goal, metering and monitoring are critical elements, according to the team. The building’s performance can be monitored down to the occupant level, Sielcken says. Lighting, receptacle use, HVAC equipment loads, and carbon dioxide levels will all be monitored, with the resulting data integrated for display on a dashboard in the building’s lobby. “We can always trend the data to see if one particular area is using more energy than expected and we can make adjustments, even down to a single copy machine,” he says. Occupancy sensors throughout the building turn off lights when areas are not in use. Any surplus energy will be exported to the city’s power grid.

“GSA really challenged us to come up with something that is a statement for energy independence,” Hutton says. “We’re very proud of the project.”

Kim A. O’Connell writes about sustainability and preservation from Alexandria, Va.

Wayne N. Aspinall Federal Building and U.S. Courthouse

Green Team

Architect of record, design/build contractor, general contractor: The Beck Group, beckgroup.com—Frank X. Eppink, Mark Hutton, Michael Murray, Louis Sierra

Building envelope: Weidlinger Associates, wai.com

Civil engineer: Del-Mont Consultants, del-mont.com—James Roberts

Client, owner: U.S. General Services Administration, gsa.gov—Susan Damour, Jason S. Sielcken

Commissioning agent: ME Group, megroup.com—Ravi Maniktala

Construction manager: Jacobs, jacobs.com—Janet Goodman, AIA, Michael Hogan, AIA

Electrical engineer, historic preservation consultant, integrated engineer, interior designer, lead design architect, lighting designer, mechanical engineer, structural engineer, and sustainable design consultant: Westlake Reed Leskosky, wrldesign.com—Paul E. Westlake Jr., FAIA, Elicia Keebler Gibbon, AIA, Fonda Hosta, Ruth Albertelli, Roger Chang, AIA, V. Mitchell Lyles, Timothy Baker, Stehpanie Banfield, Robert Smolinski, Carmen Mazzant

Design-build partners: The Beck Group; Westlake Reed Leskosky

Fire protection: Protection Engineering Group, pegrouppc.com—Thomas W. Gardner

MATERIALS

Adhesives, coatings, and sealants: Tandus, tandus.com; Shaw, shawcontractgroup.com; Forbo, www.forboflooringna.com; VPI, vpicorp.com; Mohawk, mohawkgroup.com

Building-management systems and services: Honeywell, honeywell.com; Siemens, siemens.com

Carpet: Shaw; Tandus; Lees, leescarpet.com

Ceilings: Armstrong, armstrong.com

Cladding: Dal-Tile, daltile.com

Concrete and masonry: Holcim Cement, www.holcim.us; Whitewater Building Material, www.acsol.net/~whiteh2o

Fabrics: Phifer Inc., phifer.com

Flooring: Forbo, www.forboflooringna.com; VPI; Mannington, mannington.com; Roppe, roppe.com; Johnsonite, johnsonite.com; Design Surface Distributors, designsurfacesdist.com; Stone Peak, stonepeakceramics.com

Glass: 3M Products, 3m.com; Oldcastle BuildingEnvelope, oldcastlebe.com

HVAC: Addison, www.addison-hvac.com; Armstrong, armstrongpumps.com; Mitsubishi, mitsubishipro.com; Nailor, nailor.com; Recold, spxcooling.com; Rittling, rittling.com; United Metal Products, unitedmetal.com; Williams, williamsapplied.com

Insulation: Certainteed, certainteed.com; Johns Mansville, jm.com; Knauf, knaufinsulation.us; Lapolla, lapolla.com

Interior walls: American Gypsum, americangypsum.com; Cemco, cemcosteel.com; Pacific Bulletproof, pacificbulletproof.com

Lighting: Focal Point, focalpointlights.com; G Lighting, glighting.com; Lithonia Lighting, lithonia.com; Sun Valley, usaltg.com

Lighting-control systems: EnOcean, enocean.com; NLight, nlight.net

Metal: Berridge Metal Roofing, berridge.com; Brown & Strauss Steel, brown-strauss.com; Kane Sterling, kanesterling.com; TrussBilt, trussbilt.com; Western Slope Iron, wsiron.com

Millwork: Nevamar, nevamar.com; Lamin-Art, laminart.com; WilsonArt, wilsonart.com

Paints and finishes: Sherwin Williams, sherwin-williams.com

Photovoltaics: DPW Solar, dpwsolar.com; Eaton, eaton.com; Silverback Solar, silverbacksolar.com; Sunpower, sunpowercorp.com

Plumbing and water systems: Acorn Engineering, acorneng.com; Chicago Faucets, chicagofaucets.com; EEmax, eemaxinc.com; Halsey Taylor, halseytaylor.com; Kohler, kohler.com; Sloan, sloanvalve.com; Zurn, zurn.com

Renewable-energy systems (excluding PV): Armstrong; Centennial Plastics, centennialplastics.com; Recold, spxcooling.com

Roofing: Carlisle Roofing, www.carlisle.com

Structural systems: Boise Cascade, www.bc.com

Windows and doors: LCN, lcnclosers.com; Oregon Door, oregondoor.com; Schlage, schlage.com; US Bulletproofing, usbulletproofing.com; Von Duprin, vonduprin.com

By The Numbers

Building floor area: 41,562 gross square feet

Number of occupants and visitors: 50 full-time employees; 60 visitors per day

Percent of the building that is daylit: 90% of regularly occupied spaces

Percent of the building that can be ventilated or cooled with operable windows: None

Total water used (gallons per year): 104,000 (estimated)

Calculated annual potable water use (gallons per square foot per year): 2.5 (estimated)

Total energy used (kBtu per square foot): 14 (targeted)

EPA performance rating: 100 (targeted)

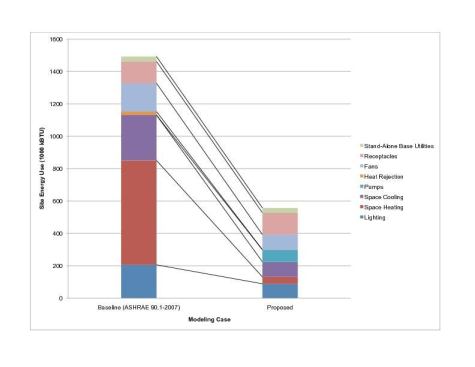

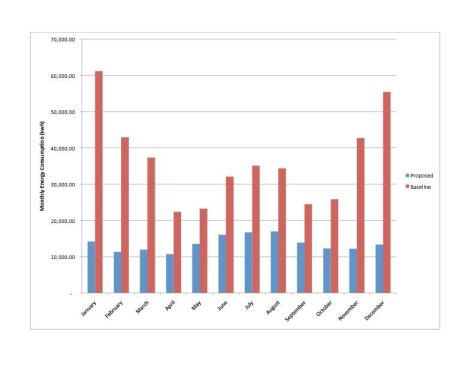

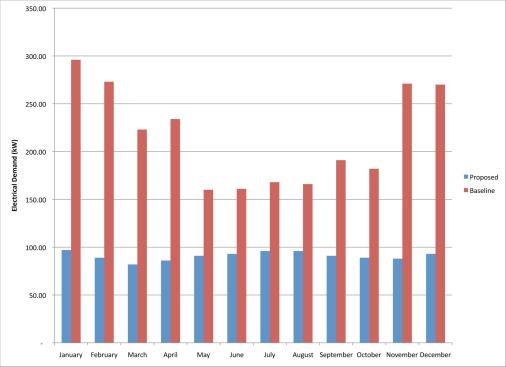

Percent total energy savings: 64% site energy-use reduction from ASHRAE 90.1-2007 baseline

LEED rating: LEED-NC 2009 Platinum (targeted)

Total project cost: $15,000,000

Data provided by the U.S. General Services Administration