This week, we’re talking about an unprecedented method for 3D printing, a pair of towers designed to bring sun to urban streetscapes, a study on the costs of building an ultra-green McDonalds, and more.

To

date, 3D printing has been characterized by the additive process of layering a

material to create an object. Carbon3D, a Silicon Valley startup, wants to change

that through its novel method that uses a controlled combination of light and

oxygen to grow components out of a photosensitive resin. The resulting objects offer

a smoother surface and are up to 100 times faster to fabricate than those made using conventional

3D printing. [3DPrint.com]

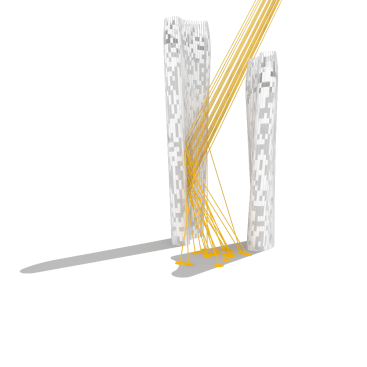

NBBJ

NBBJ's proposed towers.

Towers are only getting taller, and with more of them proposed to fill London’s skyline in the coming years, the local office of global design firm NBBJ wants to mitigate their environmental impact. A new proposal offers one solution to a particularly prescient problem—long shadows that limit the amount of sunlight that reaches street level. The two-structure concept (shown above) was designed using algorithms to optimize the light reflection off of one tower and into the shadow of the other, cutting shade between the buildings by up to 60 percent. [Wired]

McDonalds’ golden arches could one day turn green—and it has nothing to do with a Shamrock Shake. The quick-service chain recently partnered with the Rocky Mountain Institute to explore the costs and benefits of creating a net-zero version of one of its restaurants—no small task for a building category that consumes ample energy on a small footprint. [Rocky Mountain Institute]

Researchers

at Rice University in Houston have found a way to predict and compare physical properties such as stiffness, strength, and toughness for some natural and

synthetic materials—from mother of pearl to graphene—whose construction is

characterized by ultra-thin layers and nano-scale stacks. The research team explains their work in the video above. [Phys.org]